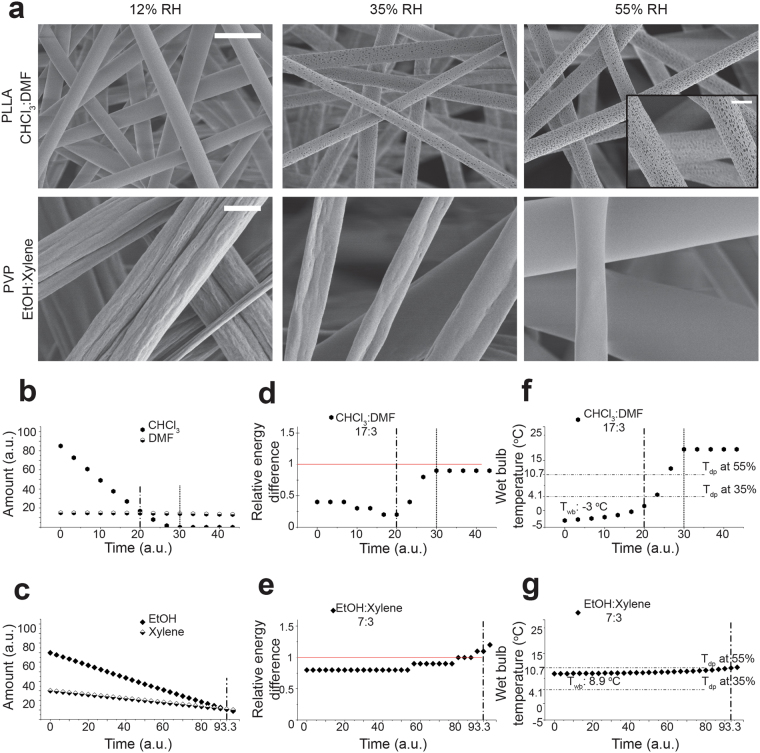

Figure 5.

Resulting PLLA and PVP fiber morphologies, Simulated solvent evaporation and RED value changes during PLLA and PVP fiber formation: (a) SEM micrographs of PLLA electrospun fibers from CHCl3:DMF (17:3) solution (upper row) and PVP electrospun fibers from EtOH:Xylene (14:6) solution (lower row) at 12, 35, 55% RH, respectively (scale bar: upper row 5 µm, inlet 2 µm, lower row 1 µm), simulated evaporation of (b) CHCl3 and DMF and (c) EtOH and Xylene from PLLA and PVP solutions, respectively (assuming the initial total amount of a solution is 100 parts and the solvent amount changes by evaporation during electrospinning), simulated RED value change during solvent evaporation from (d) CHCl3:DMF and (e) EtOH:Xylene solutions, wet bulb temperature change (°C) during solvent evaporation from (f) CHCl3:DMF and (g) EtOH:Xylene solutions, (dash-dot line) last time point of similar amounts of solvent (S) and non-solvent; (round dot line) time point S = 0; (red line) solubility limit for the polymer in the solvent system.