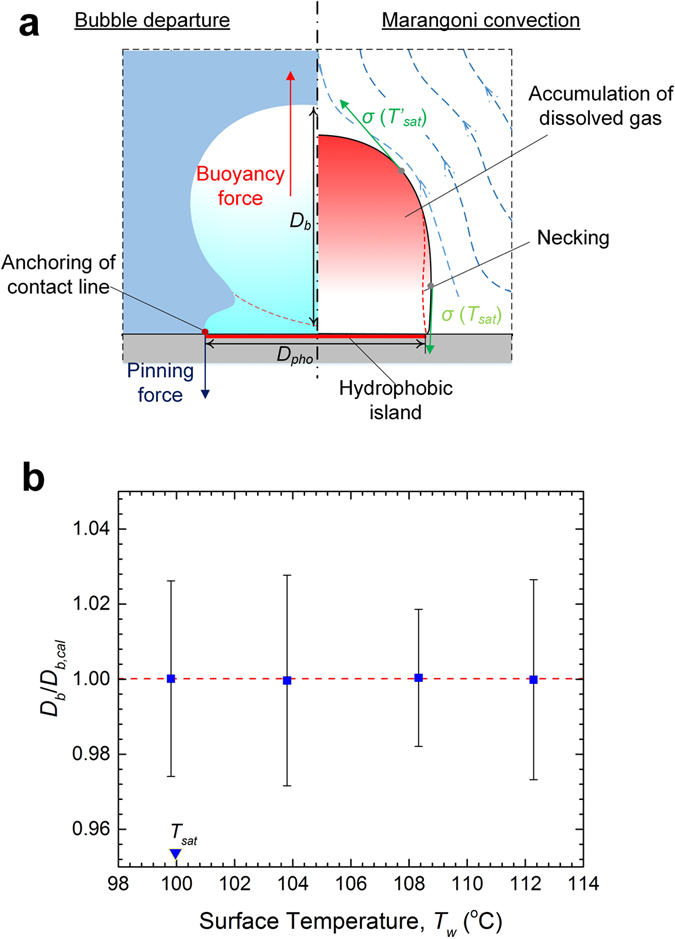

Figure 4.

Bubble departure mechanism. (a) Surrounded by subcooled liquid, the stationary bubble sitting on the hydrophobic surface assumes an elongated slug shape, as the three-phase contact line is pinned at the end of the non-wetting domain. The increasing buoyancy force results in continuous thinning and stretching of the neck section of the bubble, which leads ultimately to its rupture. Dissolved gas in the water is gasified during evaporation, and ends up being entrained into the bubble by the incoming vapour. The accumulation of gas results in a significant temperature difference between the gas-depleted bottom and gas-rich top of the bubble. The surface stress imbalance contributes to strong thermocapillary effect. (b) Plot of the experimentally measured bubble departure diameter, D b, versus the calculations by equation (4), D b,cal. The cofactor in the present empirical correlation, D b,cal = Λ(x g), depends on the mole fraction of gas within the bubble, Λ(x g) = (0.944 ± 7.398 × 10−4) + (0.0648 ± 2.590 × 10−3) × x g. Here = [6D pho σ/g(ρ l − ρ v)]1/3 is the modified characteristic capillary length. Error bar: spread of individual measurements over five consecutive bubble growth periods.