Table 1. Coupling reaction of CO2 and epoxides with catalyst 1 a .

| |||||||||||

| Entry | Epoxide | [Epoxide]: [(1)] | p [bar] | T [°C] | Time [h] | Yield [%] | TON b | TOF c [h–1] | Selectivity (NMR) d [PC] : [CC] : [PE] | Terpolymer composition (NMR) e [PC] : [PPC] : [CC] | M n (PDI) f , g [kg mol–1] |

| 1 | CHO | 2000 | 40 | 50 | 0.2 | 57 | 1150 | 5520 | 93 : 0 : 7 | — | 134 (1.7) g |

| 2 | CHO | 4000 | 40 | 50 | 0.58 | 50 | 2010 | 3440 | 91 : 0 : 9 | — | 135 (1.4) g |

| 3 | PO h | 1000 | 30 | 25 | 20 | 56 | 560 | 30 | 62 : 38 : 0 | — | 98 (1.4) f |

| 4 | PO h | 1000 | 30 | 50 | 1 | 12 | 120 | 120 | 3 : 94 : 3 | — | — |

| 5 | PO | 500 | 30 | 25 | 3 | 32 | 160 | 53 | 78 : 22 : 0 | — | 21 (1.2) f |

| 6 | SO | 1000 | 30 | 25 | 20 | 51 | 510 | 26 | 66 : 34 : 0 | — | 20 (1.3) g |

| 7 | OO | 1000 | 40 | 40 | 24 | 92 | 920 | 38 | 33 : 66 : 0 | — | 107 (1.7) f |

| 8 | ECH | 1000 | 30 | 40 | 16 | 44 | 440 | 28 | 0 : 100 : 0 | — | — |

| 9 | LO | 250 | 30 | 40 | 16 | 73 | 90 | 180 | 100 : 0 : 0 | — | 33 (1.9) f |

| 10 | LO/PO | 250/600 | 30 | 25 | 6 | 40 | 330 | 55 | 98 : 2 : 0 | 51 : 47 : 2 | 95 (1.4) f |

| 11 | CHO/PO | 500/500 | 30 | 25 | 14 | 65 | 650 | 46 | 99 : 1 : 0 | 59 : 40 : 1 | 272 (1.3) f |

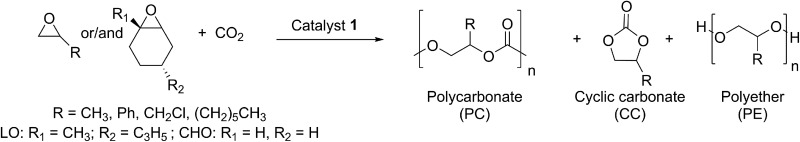

a Reaction scheme refers to copolymerisation of PO, SO, OO, ECH with CO2 (PLimC, PCHC and terpolymers look different).

b The turnover number (TON) is the ratio of the number of moles of epoxide consumed to the number of moles of catalyst.

c TOF is TON/time.

d [PC] : [CC] : [PE], assigned by the relative integrals of the signals for polycarbonate (PC), cyclic carbonate (CC) and polyether (PE).

e [PC] : [PPC] : [CC], assigned by the relative signals for (a) entry 10: PLimC : PPC : cPC (b) entry 11: PCHC : PPC : cPC before precipitation.

f Determined by GPC, calibrated with polystyrene standards in chloroform.

g Determined by GPC, calibrated with polystyrene standards in thf.

h 5.0 mL toluene.