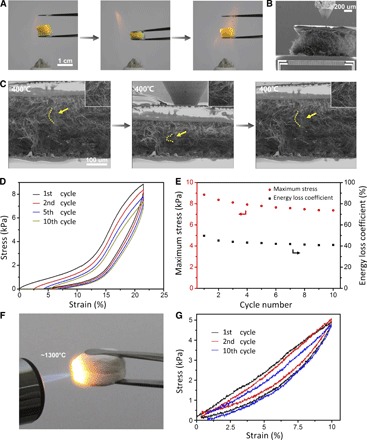

Fig. 3. Compressive test results of nanofiber sponge at high temperatures.

(A) Compression and recovery processes of macroscopic TiO2 sponge in the flame of an alcohol lamp. (B) SEM image of TiO2 sponge pressed by a nanoindenter on the loading stage with a MEMS heating system. (C) In situ SEM images of compressive process of TiO2 sponge at 400°C. The insets show the bending and springback of single nanofiber remarked in (C). (D) Stress-strain curves of TiO2 sponge with a density of ~40 mg/cm3 at 400°C for 10 cycles. (E) Variation of energy loss coefficient and maximum stress with cycle number of TiO2 sponge in (D). (F) YSZ sponge heated by a methane flame. (G) Stress-strain curves of YSZ sponge at 800°C for 10 cycles.