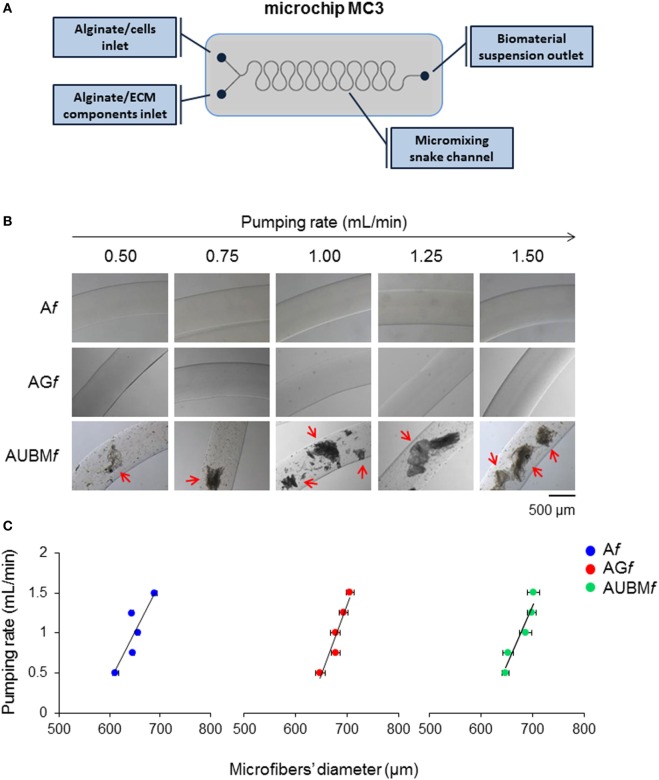

Figure 1.

Production and characterization of composite microfibers. (A) Schematic representation of the snake micromixing microfluidic device employed for the production of composite microfibers. The device presents two inlets where the alginate suspension containing cells or gelatin or UBM were delivered through the micromixing snake geometry channel and a 700-µm outlet tube (#T3) into a BaCl2 solution in order to obtain alginate (Af), alginate plus gelatin (AGf), or alginate plus UBM (AUBMf) microfibers. (B) Photomicrographs of Af, AGf, and AUBMf obtained at different pumping rates (from 0.5 to 1.5 mL/min). Arrows indicate the presence in AUBMf of UBM particles, in form of flat flakes. Bar corresponds to 500 µm. (C) Effect of the pumping rate on the dimension of the produced microfibers.