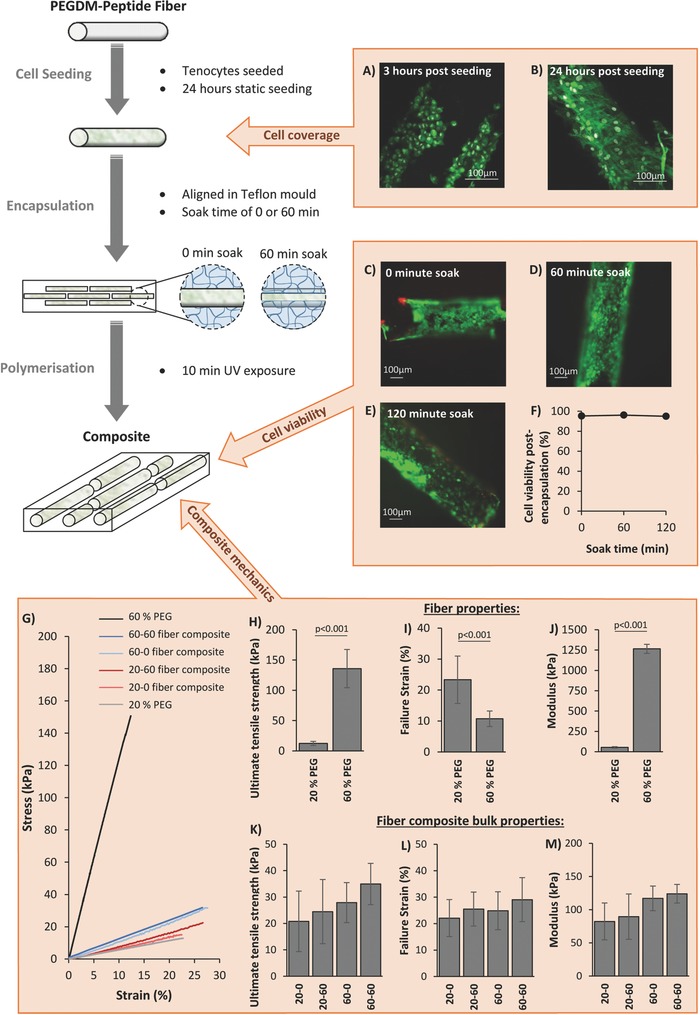

Figure 2.

Composites are manufactured via a three‐step procedure as shown in the schematic on the left. Peptide‐PEG fibers are first seeded with cells in a static culture condition for 24 h, after which they are encapsulated in a hydrogel precursor solution with PEGDM and photoinitiator. The solution is then left to soak for a fixed amount of time to control the extent of precursor penetration into the fibers, and then polymerized under ultraviolet light to produce the final composites. Confocal images of tenocytes (stained with Alexa Fluor 488 Phalloidin (green) and 4′,6‐diamidino‐2‐phenylindole (DAPI) (gray) to show the F‐actin in the cytoskeleton and the nucleus, respectively) after 3 h A) postseeding on PEG‐YRGDS fibers showed cells attach to fibers, but exhibit a compact spherical shape. B) After 24 h the cells are spreading across the fiber surface and possessing longer F‐actin filaments. C–F) Soaking cell seeded fibers for either 0, 60, or 120 min in 20% PEG matrix solution before polymerization did not significantly affect cell viability (images C–E show cells stained with Calcein AM (green) and ethidium homodimer (red), and graph F shows average cell viability after 0, 60, or 120 min soak before polymerization, n = 6). 60% PEG was found to be significantly stiffer than 20% PEG, showing a higher ultimate tensile strength (H), failure strain (I), and modulus (J) than 20% PEG. Average bulk mechanical properties of composites made with 20% or 60% PEG‐YRGDS fibers seeded with cells and soaked for either 0 or 60 min prior to polymerization (n = 9–13) were found to be similar between composite types, with no significant difference between ultimate tensile strength (K), failure strain (L), and modulus (M). Bar graphs show mean with SD as error bars and composite types are labeled as “XX–YY” where “XX” describes the % PEGDM used to make fibers, and “YY” is the fiber soak time in minutes prior to polymerization. “p” values represent significant differences between groups as calculated from a one way ANOVA and Tukey comparison of means.