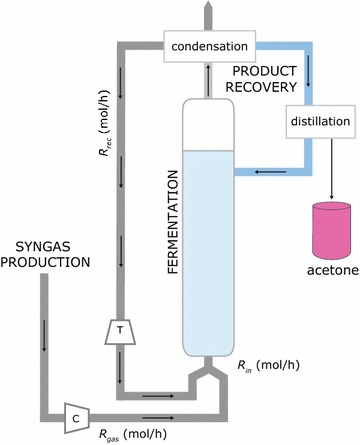

Fig. 1.

Process overview for the biological production of acetone from syngas. The fresh CO-rich gas is mixed with recycled gas and introduced into the reactor at the flow rate R in. The recycled gas leaves the condensation unit with high pressure and is passed through a turbine (T) to adjust the pressure and to generate electricity, while syngas requires compression (C). The bubble column reactor has a height of 30 m and a diameter of 6 m. CO entering the liquid phase is assumed to be completely converted to acetone by the production strain Moorella thermoacetica. Acetone leaves the reactor with the off-gas; acetone and evaporated water are condensed and then separated in a distillation step. The water from the product recovery is recycled in the reactor