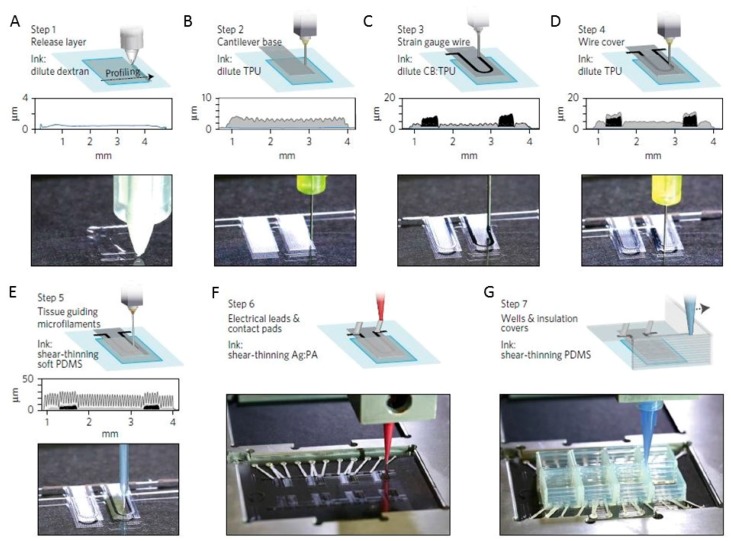

Figure 13.

Device principle and microscale 3D-printing procedure. (A) In print step 1, a 0.5-μm dextran thin-film sacrificial layer is printed; (B) In print step 2, a 3 μm TPU thin-film cantilever base is printed; (C) In print step 3, a 6.5-μm-thick CB:TPU strain sensor loop is added to the cantilever base; (D) In print step 4, a 1.5-μm TPU wire cover is added; (E) In print step 5, 20-μm-tall, 60-μm-wide PDMS microfilaments are printed in slightly overlapping lines. The filaments constitute the top part of the cantilever and guide cardiomyocytes to form anisotropic laminar tissues; (F) In print step 6, electrical leads and contact are added using a high-conductivity Ag:PA ink; (G) In print step 7, covers to insulate exposed wires and wells to contain cells and media are printed using PDMS, PLA or ABS. Reproduced from [45], with permission from © Macmillan Publishers Limited, part of Springer Nature.