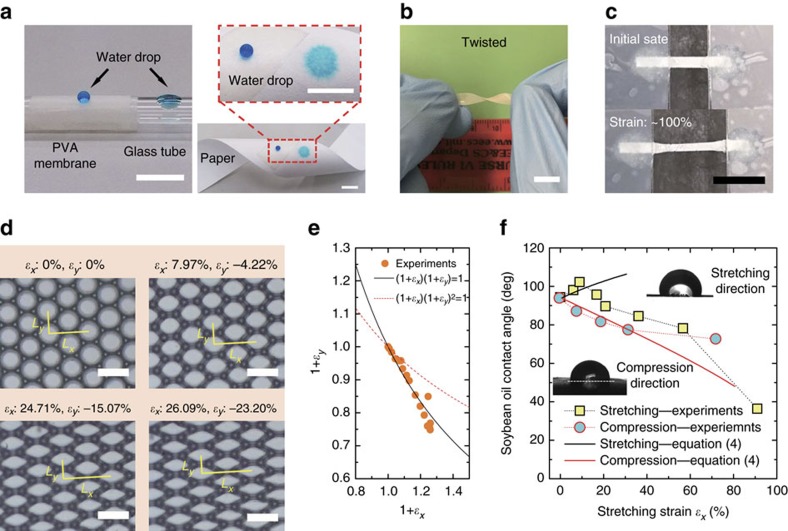

Figure 5. Flexibility of the porous omniphobic surface.

(a) PVA porous membrane coated onto a cylindrical glass tube (left) and filter paper (right) using a double-faced adhesive tape. The water droplet (dyed with methylene blue) beads up on the coating part while readily wets the naked glass (left) and permeates through the filter paper (right), respectively. (b) Twisted PVA porous membrane. (c) Unidirectional stretching of the PVA porous membrane. (d) Microscopic deformation of the cavity structure under increasing stretching strain. Here, ɛx and ɛy stand for the stretching (x direction) and compression (y direction) strain, respectively. (e) Experimental validation of the relationship (1+ɛx)(1+ɛy)=1 for ɛx<0.3. (f) Anisotropic apparent contact angles in the stretching and compression directions. Data is the average of five measurements. Scale bars are 10 mm in a–c and 100 μm in d.