Abstract

Workplace air samples analyzed for benzene at four US refineries from 1976 to 2007 were pooled into a single dataset to characterize similarities and differences between job titles, tasks and refineries, and to provide a robust dataset for exposure reconstruction. Approximately 12,000 non-task (>180 min) personal samples associated with 50 job titles and 4000 task (<180 min) samples characterizing 24 tasks were evaluated. Personal air sample data from four individual refineries were pooled based on a number of factors including (1) the consistent sampling approach used by refinery industrial hygienists over time, (2) the use of similar exposure controls, (3) the comparability of benzene content of process streams and end products, (4) the ability to assign uniform job titles and task codes across all four refineries, and (5) our analysis of variance (ANOVA) of the distribution of benzene air concentrations for select jobs/tasks across all four refineries. The jobs and tasks most frequently sampled included those with highest potential contact with refinery product streams containing benzene, which reflected the targeted sampling approach utilized by the facility industrial hygienists. Task and non-task data were analyzed to identify and account for significant differences within job-area, task-job, and task-area categories. This analysis demonstrated that in general, areas with benzene containing process streams were associated with greater benzene air concentrations compared to areas with process streams containing little to no benzene. For several job titles and tasks analyzed, there was a statistically significant decrease in benzene air concentration after 1990. This study provides a job and task-focused analysis of occupational exposure to benzene during refinery operations, and it should be useful for reconstructing refinery workers’ exposures to benzene over the past 30 years.

Keywords: Benzene, refineries, exposure assessment, industrial hygiene

Introduction

Benzene is a natural, minor constituent of crude oil, and is present in amounts varying between 0.1 and 3.0% (Verma and des Tombe, 1999). Benzene can also be produced in various refining processes, including catalytic reforming and catalytic dealkylation (Fishbein, 1988; USEPA, 1998; van Wijngaarden and Stewart, 2003; WHO 1993). Reports of occupational benzene exposure in various sectors of the petroleum industry have been described in the published literature over the past 30 years (Armstrong et al., 1996; Buchet et al., 1984; CONCAWE, 1987, 1994; Glass et al., 2000, 2001, 2005; HEI, 1988; Nordlinder and Ramnas, 1987; Rappaport et al., 1987; Runion and Scott, 1985; Verma et al., 2001; Weaver et al., 1983). In general, the information regarding exposure to benzene during refinery operations indicates that full-shift benzene exposures of refinery workers have been less than 1 part per million (ppm) since at least the mid-1980s. The published studies, however, do not provide detailed task-level exposure data or information specific to workers across individual facilities. As a result, the industry-wide datasets are difficult to use if one wishes to conduct dose reconstruction studies or to estimate the exposures of individual workers based on their job descriptions and years employed.

As part of an ongoing historical benzene exposure assessment program for ExxonMobil refineries in the US, analyses have been conducted to understand long-term average (i.e., full-shift) and task-level air concentrations at four refineries in the US located in Baton Rouge, LA; Beaumont, TX; Joliet, IL; and Baytown, TX (Gaffney et al., 2010, 2011; Kreider et al., 2010; Panko et al., 2009; Widner et al., 2011). In this study, historical benzene exposure data collected at the four refineries were reanalyzed to evaluate similarities and differences between refineries, and, where possible, provide pooled estimates of exposure across refineries to increase the robustness of the job and task-specific exposure distributions. The four refineries selected for this analysis represent two of the largest refineries in the US and two mid-size refineries (Table 1). While each of the four refineries varies in terms of production rate (barrels processed per day) and age of refinery, all have similar raw materials, intermediates, process streams and products (Table 1), process areas, job titles and tasks.

Table 1.

Process streams by refinery.

| Refinerya | Barrels of crude oil per day | Year constructed | Process streams-end product by refinery | |

|---|---|---|---|---|

| Fuels (Percent benzene) | Other (Percent benzene)b | |||

| Baton Rouge | 500,000 | 1909 | Gasoline-all grades (0.43% - 1.0%); aviation100 (0.05%); jet fuel (0.02 - 0.43%); diesel (0.02%) | LPG; butanes; fuel gas; chemical plant; lube oils and wax (ND); coke (ND); asphalt (ND) |

| Baytown | 500,000 | 1919 | Motor gasoline (0.25%–1.2%); jet fuels; kerosene; diesel fuels; varsol | Propanes, butanes, aliphatic solvents; lube based stocks; coke; asphalt; exxsol D fluids |

| Beaumont | 365,000 | 1902 | Motor gasoline (0.4–4.9%); jet fuel (<0.1%); diesel (<0.1%); fuel (<0.1%) | Ethane; propane; isobutene; butane (all <0.1%) |

| Joliet | 200,000 | 1973 | Gasoline (0.5 - 3.0%) | LPG products; distillate; sulfur; coke; asphalt (all <0.1%) |

LPG: liquid petroleum gas.

aMerger of Exxon and Mobil in 1999.

bND: Not detected.

In general, the exposure scenarios at refineries may vary depending on the variety of processing units in the plant, the type of work being conducted, and the equipment and procedures in place to reduce potential exposures. However, average benzene exposure concentrations are expected to be low during normal operations because worker activities most frequently occur in proximity to closed systems. Air concentrations may be higher when tasks that involve opening equipment are performed, particularly in areas where streams contain higher concentrations of benzene (e.g., reformer, tank farm, wastewater treatment). Because petrochemical industry engineering control systems have been improved over time in response to governmental regulations and new process and control technologies have become available, we believe that variability in worker exposure concentration is most likely to be driven by task-based activities, where there is a potential for contact with process streams, and contemporaneously available engineering controls, rather than factors such as refinery age, geographic location or production volume.

The objective of this combined analysis was to identify and characterize sources of exposure variability using the state of the art analysis of variance statistical approach recommended by American Industrial Hygiene Association and to prepare a refined dataset that should be useful in conducting future risk assessments or epidemiology studies involving benzene (Ignacio and Bullock, 2006). This combined analysis also evaluates whether personal benzene industrial hygiene data from four well-characterized refineries supported the hypotheses that (1) time period relative to regulatory initiatives, (2) process stream benzene content, and (3) and the performance of specific tasks are the critical determinants of worker benzene exposure in the time period 1976–2007.

Methods

Data collection

Air sampling data collected from four US refineries (Table 1) from 1976 through 2007 obtained from electronic databases and hard copy reports were entered into a new database and verified for accuracy against original documentation. Sampling and analytical methods spanned both short-term integrated active sampling with colorimetric or photoionization detection, and longer duration active and passive methods with charcoal media and gas chromatography-flame ionization detection. Samples were gathered from four ExxonMobil electronic databases: Personal Computer Industrial Hygiene System or Mobil Industrial Hygiene (Computer) System, Medgate, and Exposure Assessment Strategy. Information contained in these databases pertinent to our analysis included: sample date, sample duration, sample type (personal/area), analytical result, sample media, and job title, department, area and task associated with the sample. The accuracy of the information contained in all four ExxonMobil databases was verified through a separate quality control review of the corresponding paper records associated with 25% of the air sample results. The documents, including physical sample sheets, industrial hygiene survey reports, and lab reports were reviewed. The results were then compared to an acceptable error rate determined a priori of no more than 5% critical errors. An error was considered critical if it involved the sample result (e.g., concentration, lab result, units, qualifier). All other errors, including typographical errors, were considered non-critical, given that they would not lead to miscalculation of the airborne concentration. Overall, based on the fact that there were less than 0.5% (Baton Rouge); less than 0.8% (Baytown); less than 1.5% (Beaumont); and less than 3% (Joliet) critical errors in the database, it was concluded that the database accurately reflected the original documentation. For any errors (typically transcription errors) found during the verification process, appropriate changes were made to the database.

Both personal and area samples were collected from all four refineries; however, the focus of the analysis is on personal exposure; therefore area samples are not included (Gaffney et al., 2010, 2011; Kreider et al., 2010; Panko et al., 2009). Further, personal data were collected from refinery areas including dock and loading areas at all or some of these facilities; however, the focus of this analysis is strictly on data from the refinery areas excluding the dock and loading areas. Additional information regarding refinery processes, job and task descriptions, benzene process changes, industrial hygiene surveys, personal protection practices, and relevant exposure assessment initiatives was gathered from industrial hygiene surveys and program documentation, and interviews of personnel. Detailed data collection methods for individual refineries have previously been described (Gaffney et al., 2010, 2011; Kreider et al., 2010; Panko et al., 2009).

Data analysis

Personal air samples collected during routine, turnaround, and startup operations were categorized by area, job title, and task description. Air samples were also classified by sample duration (i.e., <180 min and >180 min). Samples less than 180 min were considered task samples representative of peak- or task-specific exposures. Samples with durations of 180 min or greater were considered non-task samples, as they most likely characterized more than one task performed by a worker as part of routine job duties and were not task specific. Samples were also classified as non-task samples when the sample collection time could not be determined.

Each personal air sample collected at these four refineries was assigned to one of 50 job titles and one of 48 work areas. Additionally, the numerous tasks conducted by workers at the refinery were consolidated into 24 task bins based on the nature of the task. Cross-refinery standardized job titles, work areas, and task bins were established to represent these categories across all four refineries. Definitions of job titles, areas, and tasks have previously been published (Gaffney et al., 2010, 2011; Kreider et al., 2010; Panko et al., 2009). The protocol for assigning job title, work area, and task assignments was reviewed by ExxonMobil industrial hygienists, including the authors, to ensure that samples were properly characterized.

The benzene concentration data for the non-task and task datasets were tested for distribution fit using the Kolmogorov–Smirnov goodness-of-fit test for a normal, lognormal, and gamma distribution, and none of these distributions (p < 0.05) were found at a 95% confidence level. However, the data were found to be approximately lognormal based on visual examination of probability plots.

Censored data (that is, those samples less than the limit of detection) were included in the statistical analysis using the regression on order statistics (ROS) method for a lognormal distribution, which is equivalent to the robust log probit regression method presented in the literature (Helsel, 2005; Hewett 2007; Ignacio and Bullock, 2006; USEPA, 2007). The general approach of the ROS method includes fitting a linear regression model of the detected values of the dataset to the quantiles of the assumed distribution (values from the y-axis of a probability plot) and replacing the values for samples less than the limit of detection with the values extrapolated from the linear regression (Helsel, 2005). Because this dataset has multiple limits of detection associated with it, the robust ROS method developed by Helsel and Cohn was used (Helsel and Cohn, 1988). This method was used instead of the typical substitution method (i.e. substituting the limit of detection by the limit of detection divided by 2 or the √2) because it produces fairly robust estimates of the mean and standard deviation even with modest departures from the lognormal distribution and if 50–70% of the data are below the limit of detection (Baccarelli et al., 2005; Huybrechts et al., 2002; Ignacio and Bullock, 2006; Lubin et al., 2004).

Similarities and differences between potential exposure groups or tasks were evaluated using analysis of variance (ANOVA) models in SYSTAT version 11. The most frequently sampled job titles and task bins across refineries were evaluated to identify potential significant differences (p < 0.05) in exposure distributions between refineries. When statistically significant differences were noted, in general there was a small magnitude of absolute differences in concentrations. Therefore, based on professional judgment, samples were pooled across refineries prior to calculation of summary statistics and further analyses; the results of this analysis are presented below.

An ANOVA model was subsequently used to determine if any of the area categories could be pooled together for non-task samples or if job title categories could be pooled together for task samples to increase the sample size of each group. The analysis consisted of identification of area-job title combinations that had statistically significant differences in benzene concentrations compared to the average for that job title for the non-task data. A similar analysis was conducted for job title-task bin combinations that had statistically significant differences in benzene concentrations compared to the average for the task bin. The Tukey multiple comparison test was used to identify differences at a 95% confidence level (Neter et al., 1990). This analysis reduced an initial set of 362 different job title-area categories and 129 different task-job title combinations to a more focused set of task and non-task similar exposure categories. ANOVA was also utilized to identify potential differences between exposure distributions based on normal, startup or turnaround operational status. The outcome of these analyses was the identification of area or job categories requiring separate characterization from the other areas or job titles for a given job title (non-task) or task bin (task) because their benzene concentrations were statistically significantly different.

Because these data are approximately lognormal, the natural log transformed sample results, including non-detect values estimated by the ROS model were used in the ANOVA models for the non-task and task data. The categories used to present the data were based on the results of the ANOVA and post-hoc pair-wise analysis. Summary statistics were calculated for these final job categories and task bins.

To determine if there was a decrease in air concentration after 1990 by any job category, pair-wise comparisons were made to identify statistical differences between samples collected from two time periods: 1976–1989 and 1990–2007. The year 1990 was used as the cutoff point as the majority of regulations intended to reduce employee exposure to benzene and to reduce benzene emissions to the ambient environment from petroleum refineries were adopted by 1990 (OSHA, 1987; USEPA, 1989). To meet the requirements of the new regulations, various controls (e.g. closed system drains, internal floating roofs with specific seals, closed sample points, and vapor recovery systems for loading facilities) were implemented at most of the refineries by 1990.

Results

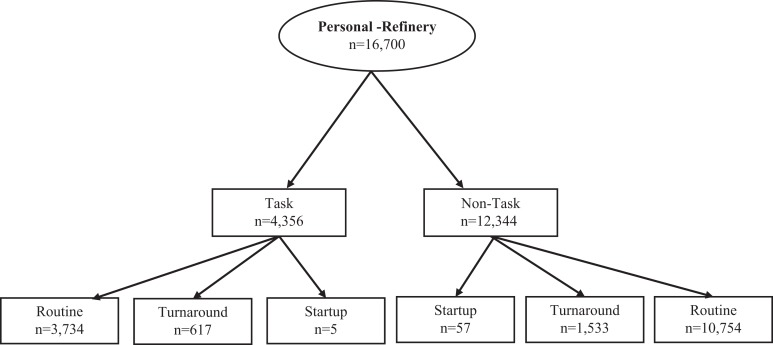

In total, 16,700 personal samples collected at refinery locations were compiled for this analysis. 12,344 samples were characterized as non-task samples (≥180 min) and 4356 were characterized as task samples (<180 min). Of the 12,344 non-task samples, 351 samples had an unknown sample collection time. These samples with unknown sample times were conservatively categorized as non-task samples in order to not dilute the task data. Of the non-task samples, 10,754 were taken during routine operations, 1533 during turnarounds, and 57 during unit startup. Of the task samples, 3734 were taken during routine operations, 617 during turnarounds, and five during unit startup (Figure 1).

Figure 1.

Data Breakdown (1976-2007).

The frequency of samples taken for each area, job, or task bin was consistent with the sampling strategy at each facility which targeted areas, jobs, or tasks with an increased likelihood of exposure to benzene. For example, the greatest number of personal samples were collected in areas that are expected to have process streams or liquid products containing higher concentrations of benzene based on professional judgment (Table 2). Those areas with fewest samples generally have low benzene exposure potential, or represented special scenarios.

Table 2.

Number of samples collected compared to areas with expected benzene containing process streams.

| Benzene concentration range groupa | Areasb | Number of samples collectedc | Areas |

|---|---|---|---|

| A | Oil movements, reformer, tank farm, waste treatment | >500 | Catalytic cracker, coker, desulfurization, hydrofiner, laboratory, light ends unit, oil movements, pipestill, reformer, waste treatment, tank farm |

| B | Catalytic cracker, catalytic light ends unit, coker, desulfurization, gas blending, gas collection, hydrocracker, hydrofiner, isomerization, light ends unit, pipestill, solvents fractionating unit, solvents hydrogenation unit, WCLA | 100–500 | Alkylation plant, catalytic light ends unit, dewaxing area, hydrocracker, isomerization, lube blending and storage, lube extraction unit, shops, utilities |

| C | Administration, alkylation plant, asphalt plant, deasphalting unit, dewaxing area, drum storage, gas plant 3, hydrogen generation unit, lube blending and storage, lube extraction unit, lube rack, medical, MEK unit, MTBE production, propane storage, SO2 plant, utilities | <100 | Administration, analyzers, asphalt plant, cracking/reforming, deasphalting unit, distillation (lubes, oil movements, utilities), drum storage, landfill, LE rack, lube rack, medical, garage, gas collection, gas plant 3, gas blending, hydrogen generation unit, MEK unit, MTBE production, plant wide, propane storage, safety, site motorized, SO2 plant, solvent fractionating unit, solvents hydrogenation unit, store house, WCLA, wax rack |

WCLA: waste water clarification unit; MEK: methyl ethyl ketone; MTBE: methyl tertiary butyl ether; LE: light ends.

aExpected benzene concentration by area ranked from higher to lower concentration (A to C); rankings based on professional judgment of ExxonMobil Industrial Hygienists. Only areas where task samples were collected were ranked.

bAreas where concentration varies: laboratory, shops, garage, plant wide, analyzers, distillation (lubes, oil movements, utilities).

cNumber of all samples (task and non-task) collected across four facilities.

In addition, the greatest number (80%) of non-task personal air samples were collected on workers whose job duties involve potential contact with process streams containing higher concentrations of benzene (Table 3). The same trend holds true for task samples, where the tasks most often sampled (83%) involve potential contact with process streams containing higher concentrations of benzene (Table 4).

Table 3.

Non-task benzene air concentrations by job title, operational status, and area.

| Job title (percent of total)a | Description of duties | Status | Area(s) | n | Detection frequency (%) | Benzene concentration (ppm) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mean | Standard deviation | Geometric mean | Geometric standard deviation | 75th percentile | 95th percentile | Minimum detected | Maximum detected | ||||||

| Process technician (48%) | Process operations, such as draining process equipment or lines prior to work and taking samples of process streams | Routine | Lube blending and storage | 135 | 6% | 0.015 | 0.041 | ND | ND | ND | 0.055 | 0.034 | 0.39 |

| Hydrofiner | 299 | 44% | 1.1 | 7.0 | ND | ND | 0.18 | 1.0 | 0.010 | 91 | |||

| Hydrocracker | 138 | 62% | 0.074 | 0.11 | 0.023 | 7.5 | 0.093 | 0.26 | 0.010 | 0.95 | |||

| Reformer | 908 | 47% | 0.084 | 0.15 | ND | ND | 0.11 | 0.24 | 0.0090 | 2.0 | |||

| Waste treatment | 697 | 58% | 0.13 | 0.19 | 0.037 | 7.1 | 0.20 | 0.45 | 0.0080 | 1.6 | |||

| Tank farm | 224 | 54% | 0.090 | 0.30 | 0.014 | 7.0 | 0.060 | 0.34 | 0.010 | 3.6 | |||

| Pipestills | 357 | 43% | 0.074 | 0.33 | ND | ND | 0.040 | 0.19 | 0.010 | 5.1 | |||

| Analyzer | 18 | 100% | 0.12 | 0.19 | 0.069 | 2.8 | 0.090 | 0.44 | 0.010 | 0.80 | |||

| All other areas | 2540 | 29% | 0.068 | 1.0 | ND | ND | 0.028 | 0.16 | 0.006 | 49 | |||

| Startup | All areas | 57 | 39% | 0.041 | 0.062 | ND | ND | 0.040 | 0.16 | 0.015 | 0.29 | ||

| Turnaround | Hydrocracker | 39 | 95% | 0.17 | 0.28 | 0.077 | 3.3 | 0.12 | 0.93 | 0.030 | 1.3 | ||

| Reformer | 133 | 77% | 0.28 | 0.88 | 0.055 | 7.2 | 0.21 | 1.19 | 0.0070 | 9.2 | |||

| All other areas | 381 | 43% | 0.049 | 0.093 | ND | ND | 0.048 | 0.24 | 0.010 | 0.52 | |||

| Machinist (12%) | Equipment maintenance/repair on refinery units | Routine | Waste treatment | 309 | 74% | 0.34 | 0.74 | 0.087 | 7.7 | 0.34 | 0.91 | 0.010 | 6.2 |

| reformer | 68 | 57% | 0.51 | 1.6 | 0.045 | 12 | 0.19 | 2.1 | 0.040 | 11 | |||

| All other areas | 958 | 31% | 0.074 | 0.39 | ND | ND | 0.038 | 0.26 | 0.0050 | 7.7 | |||

| Turnaround | Lube extraction unit | 49 | 33% | 0.021 | 0.025 | ND | ND | 0.035 | 0.06 | 0.024 | 0.06 | ||

| Reformer | 39 | 90% | 0.28 | 1.1 | 0.082 | 3.4 | 0.12 | 0.32 | 0.030 | 7.0 | |||

| All other areas | 97 | 52% | 0.065 | 0.11 | 0.020 | 6.5 | 0.060 | 0.29 | 0.020 | 0.76 | |||

| Pipefitter/welder (10%) | Piping maintenance, including blinding and breaking of lines | Routine | Reformer | 77 | 74% | 0.69 | 1.8 | 0.093 | 8.1 | 0.49 | 3.1 | 0.010 | 12 |

| Waste treatment | 71 | 69% | 0.12 | 0.19 | 0.034 | 6.7 | 0.13 | 0.53 | 0.0050 | 0.92 | |||

| All other areas | 777 | 37% | 0.12 | 0.88 | ND | ND | 0.036 | 0.31 | 0.0010 | 16 | |||

| Turnaround | Reformer | 135 | 75% | 0.44 | 1.6 | 0.061 | 8.4 | 0.20 | 1.9 | 0.013 | 15 | ||

| Lube extraction unit | 46 | 26% | 0.029 | 0.061 | ND | ND | 0.023 | 0.13 | 0.013 | 0.32 | |||

| All other areas | 168 | 61% | 0.11 | 0.27 | 0.026 | 6.2 | 0.11 | 0.41 | 0.010 | 1.9 | |||

| Laboratory technician (10%) | Analysis of samples of process streams and other laboratory work | Routine | All areas | 1187 | 58% | 0.17 | 0.71 | 0.024 | 8.1 | 0.11 | 0.60 | 0.0035 | 14 |

| All | All areas | 12344 | 43% | 0.21 | 2.4 | ND | ND | 0.070 | 0.44 | 0.0010 | 140 | ||

| Routine | All areas | 10754 | 42% | 0.21 | 2.3 | ND | ND | 0.070 | 0.42 | 0.0010 | 140 | ||

| Startup | All areas | 57 | 39% | 0.041 | 0.062 | ND | ND | 0.040 | 0.16 | 0.015 | 0.29 | ||

| All Job Titlesb | Turnaround | All areas | 1533 | 49% | 0.25 | 3.1 | ND | ND | 0.080 | 0.53 | 0.0040 | 103 | |

| 1976–1989 | All areas | 7259 | 53% | 0.27 | 2.6 | ND | ND | 0.12 | 0.55 | 0.0050 | 140 | ||

| 1990–2007 | All areas | 5066 | 29% | 0.14 | 2.0 | ND | ND | 0.026 | 0.21 | 0.0010 | 103 | ||

aTotal percentage for job titles shown is 80%.

bTotal includes all job titles; Year of sample collection, unknown for 19 samples. ND: Geometric mean and geometric standard deviation not calculated because more than 50% of the samples were below the limit of detection. Percentile not calculated because the proportion of results below the detection limit exceeds the selected percentile.

Table 4.

Task benzene air concentrations by task bin and area.

| Task Bin (percent of total)a | Description of task | Status | Area(s) | n | Detection frequency (%) | Benzene Concentration (ppm) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mean | Standard deviation | Geometric mean | Geometric standard deviation | 75th percentile | 95th percentile | Minimum detected | Maximum detected | ||||||

| Blinding and breaking (31%) | Installing blinds, breaking lines or opening equipment (including coke drums) and installing or removing equipment that has typically been drained | All | Reformer | 576 | 58% | 2.7 | 8.6 | 0.18 | 16 | 1.5 | 13 | 0.018 | 107 |

| All | Tank farm | 20 | 65% | 14 | 30 | 0.73 | 21 | 2.2 | 80 | 0.73 | 105 | ||

| All | All other areas | 572 | 24% | 0.53 | 2.7 | ND | ND | ND | 1.8 | 0.020 | 39 | ||

| Blinding and breaking-undrained (1%) | Installing blinds, breaking lines or opening equipment and installing or removing equipment confirmed to not have been drained prior to line break | All | All areas | 53 | 47% | 0.52 | 0.96 | 0.06 | 14 | 0.53 | 2.5 | 0.032 | 4.71 |

| Sample collection (20%) | Collecting process sample from line/unit | All | All areas | 770 | 28% | 0.51 | 2.3 | ND | ND | 0.15 | 2.6 | 0.010 | 47 |

| Equipment cleaning and repair (13%) | Maintaining or repairing units/equipment, calibrating equipment or meters, changing or cleaning filters and screens, and cleaning equipment | All | All areas | 483 | 36% | 1.1 | 6.0 | ND | ND | 0.20 | 4.2 | 0.0060 | 100 |

| Sample analysis (10%) | Laboratory analysis of samples including washing of glassware, pouring of samples, disposing of samples, and other laboratory work | All | All areas | 387 | 44% | 1.0 | 4.4 | ND | ND | 0.38 | 4.0 | 0.025 | 58 |

| Gauging (8%) | Gauging tanks to determine liquid levels | All | All areas | 284 | 11% | 0.16 | 0.95 | ND | ND | ND | 0.37 | 0.014 | 12 |

| All assigned tasksb | All | All areas | 3768 | 35% | 1.1 | 5.5 | 0.051 | 12 | 0.26 | 3.6 | 0.0060 | 107 | |

| 1976-1989 | All areas | 1615 | 53% | 1.9 | 7.6 | 0.40 | 3.0 | 0.78 | 8.4 | 0.00011 | 107 | ||

| 1990-2006 | All areas | 2141 | 22% | 0.40 | 3.0 | 0.22 | 2.4 | 0.090 | 1.4 | 0.000055 | 100 | ||

aTotal percentage for tasks shown is 83%.

bTotal includes all short term samples except where task bin could not be assigned (n = 588). Year of sample collection unknown for 12 samples. ND: Geometric mean and geometric standard deviation not calculated because more than 50% of the samples were below the limit of detection. Percentile not calculated because the proportion of results below the detection limit exceeds the selected percentile.

The distributions of personal benzene air concentrations for the most frequently sampled cross refinery job titles (process technician, laboratory technician, machinist, and pipefitter/welder) generally indicate that no meaningful difference between refineries exists (Figure 2(a) to (d)). While variability exists, and some statistically significant differences were noted across refineries, there does not appear to be a trend that would exclude the combination of this data. For example, though a statistically significant difference (p < 0.05) was noted for the pipefitter/welder between the Beaumont and Baytown refineries, the arithmetic means were 0.27 ppm and 0.23 ppm respectively, a difference of 0.04 ppm. Generally speaking, these differences are not meaningful from an industrial hygiene perspective simply because all average values were very similar and below contemporaneous occupational exposure limits (OELs), and often within the range of analytical precision.

Figure 2.

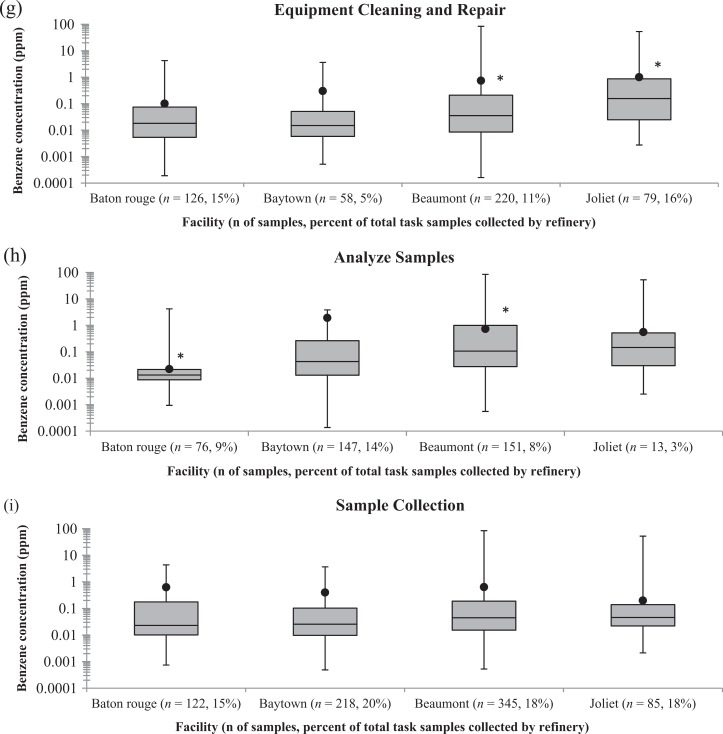

Distribution of Non-Task and Task Data by Refinery. Error bars represent minimum and maximum values; dot represents arithmetic mean, box represents 75th, 50th, and 25th percentile. (a) Process technician; *significant difference between Baytown and Baton Rouge/Beaumont/Joliet (p < 0.05); *significant difference between Beaumont and Joliet (p < 0.05). (b) Laboratory technician; *significant difference between Baton Rouge and Beaumont/Joliet (p < 0.05); *significant difference between Baytown and Beaumont/Joliet (p < 0.05). (c) Machinist; *significant difference between Baton Rouge and Baytown/Beaumont. (d) Pipefitter/welder; *significant difference between Joliet and Beaumont/Baton Rouge/Baytown (p < 0.05); *significant difference between Beaumont and Baytown. (e) Blinding and breaking; *significant difference between Beaumont and Baton Rouge/Baytown (p < 0.05); *significant difference between Joliet and Baton Rouge/Beaumont. (f) Gauging. (g) Equipment cleaning and repair; *significant difference between Beaumont and Baton Rouge (p < 0.05); *significant difference between Joliet and Baton Rouge/Beaumont/Baytown (p < 0.05). (h) Analyze samples; *significant difference between Baton Rouge and Baytown/Beaumont/Joliet (p < 0.05); *significant difference between Beaumont and Baytown. (i) Sample collection.

With regard to the distributions of personal benzene air concentrations for the most frequently sampled cross-refinery tasks (blinding and breaking, equipment cleaning and repair, gauging, sample analysis, and sample collection) an interesting trend was observed for the blinding and breaking and equipment cleaning and repair tasks (Figure 2(e) to (i)). For these two tasks, the air concentrations were statistically significantly higher at Beaumont and Joliet compared to Baton Rouge and Baytown (p < 0.05). This trend appeared to be dependent on sample size and area of the refinery, reinforcing the targeted sampling approach. For example, in 1989 alone, 247 samples were collected at the reformer at the Beaumont refinery, compared to the total number of samples collected for the same task at the Baytown refinery (n = 101). No statistically significant differences were noted for the gauging and sample collection task. These differences do not preclude the combination of task data.

Non-task exposure estimates in the refinery dataset

Influence of operational status

A statistical difference (p < 0.05) was observed between operational statuses when all job categories were considered. A comparison of normal and turnaround operations indicates that average air concentrations of benzene during turnaround operations (0.25 ppm) were slightly, but statistically significantly higher than airborne concentrations of benzene during normal operations (0.21 ppm) (Table 3).

Benzene concentration by operational status, area, and job category

The ANOVA and pair-wise comparisons indicated that air concentrations for six job titles (process technician, pipefitter/welder, machinist, contractor-laborer, contractor-catalyst, and mobile equipment operator) were influenced by the area of the refinery in which the employee was working. As a result, separate job categories were created for each job title area combination when the mean measured benzene concentration for the combination differed significantly (p < 0.05) from the pooled data for the job title across all work areas.

Benzene air concentrations for non-task samples were analyzed for each job category during routine, turnaround, and startup operations. Concentrations and associated summary statistics for the most frequently sampled job categories (process technician, pipefitter/welder, machinist, and laboratory technician) are shown in Table 3; data for all non-task samples are shown in Supplemental Table 1 (Available online at: http://tih.sagepub.com/content/by/supplemental-data). Further analysis showed that of all long-term benzene air concentrations, 98% (12,081 out of 12,344) were below the current Occupational Safety and Health Administration (OSHA) permissible exposure limit of 1 ppm.

While the initial data analysis indicates that of the most frequently sampled job categories, the process technician worker group at the hydrofiner during routine operations had the highest mean benzene concentration, 1.1 ppm (n = 299), this was the result of a small number of samples at one location. Across the four refineries, this job title-area combination had the highest mean benzene air concentration at the Baytown refinery during routine operations (1.3 ppm, n = 245) compared to Baton Rouge (0.0054 ppm, n = 33), Beaumont (0.12 ppm, n = 19), and Joliet (0.0068 ppm, n = 2). Of the 245 samples collected at the Baytown hydrofiner, 14 samples were >1 ppm and were collected prior to 1981. Twelve of these samples were collected in August and September 1978 at post ‘Number 2 NFU’ or Naphtha Fractionation Unit. The maximum concentration recorded for this job category was 91 ppm and was identified as a potential outlier based on statistical analysis. These samples likely represent an unusual event or operational difference compared to the other refineries but could not be confirmed. If these 12 samples are removed from the analysis, the overall mean decreases from 1.1 ppm (n = 299) to 0.31 (n = 287) and for Baytown, specifically, the mean decreases from 1.3 ppm (n = 245) to 0.37 ppm (n = 233). The number of samples collected at the Baytown hydrofiner and the exposure levels measured reflect the targeted sampling strategy used by ExxonMobil Industrial Hygienists. Typically at any refinery, when the process is closed and functioning normally, the concentrations of benzene are much lower. Across refineries, the process technician worker group at Baytown was statistically significantly different compared to the Baton Rouge, Beaumont, and Joliet facilities (Figure 2(a)). Although there is a significant difference, the magnitude of the difference in the average benzene air concentration measured for the process technician worker group across all four refineries ranges from 0.048 to 0.26 ppm and is within an order of magnitude, and well below 1 ppm (Figure 2(a)).

Benzene concentrations by time period

A number of the most frequently sampled job categories demonstrated a statistically significant decrease in benzene air concentrations after 1990 (Figure 3(a)). For example, the average concentration for the process technician worker group at the hydrofiner during routine operations decreased from 1.43 ppm before 1990 (n = 230) to 0.018 ppm after 1990 (n = 69). For the process technician ‘all other areas’ job category, although the 95th percentile decreased, the mean increased from 0.061 to 0.075 ppm. This is likely due to the fact that one sample collected in 1994 at Baytown in the oil movements area had a result of 48.9 ppm. If this sample was excluded as an operational outlier, the respective mean would be 0.034 ppm, and would demonstrate a statistically significant decrease in benzene air concentration after 1990.

Figure 3.

(a) Distribution of non-task benzene air concentrations by job category and time. PT: process technician; Mach: machinist; LT: laboratory technician; PF: pipefitter/welder; HDF: hydrofiner; WT: waste treatment; RF: reformer; AO: all other areas; TA: turnaround status. Concentrations for the job titles shown were significantly different by time period (p < 0.05). (b) Distribution of task benzene air concentration by task bin and time. Concentrations for the tasks shown were significantly different by time period (p < 0.05).

Task exposure estimates in the refinery dataset

Influence of operating status

Unlike the non-task dataset, operational status did not have a significant effect (p < 0.05) on task-specific concentrations, and thus task level samples were not analyzed separately based on operational status.

Benzene concentration by task bin

Benzene air concentrations and related summary statistics for the most frequently sampled tasks, including blinding and breaking; sample collection-process; equipment cleaning and repair; gauging; and sample analysis-laboratory are shown in Table 4. Complete task data and summary statistics for task samples representing 24 separate task bins are summarized in Supplemental Table 2 (Avaliable online at: http://tih.sagepub.com/content/by/supplemental-data). The ANOVA and pair-wise comparisons indicated that the area in which these tasks were performed did not influence the benzene concentrations associated with the tasks, except for the blinding and breaking task. Separate categories were created for blinding and breaking at the reformer and tank farm. In addition, job title also had an effect on the blinding and breaking (pipefitter and machinist, n = 899) and the equipment cleaning and repair tasks (tank equipment cleaner, n = 6).

Of these tasks, the highest mean benzene air concentration was associated with the blinding and breaking task at the Joliet and Baytown tank farms (14 ppm; n = 20). The majority of these samples were collected during routine operations and the task was primarily performed by pipefitters. Five of the 20 samples were greater than 5 ppm. The data is a reflection of the targeted sampling strategy of tasks that involved opening of equipment, and hence an increased exposure potential compared to exposure when the equipment is closed.

According to the ExxonMobil industrial hygiene program, work permit systems, gas testing programs, and the percent benzene content drove the use of respiratory protection (in addition to other personal protective equipment and controls) to ensure worker protection over time.

For all tasks, except the blinding and breaking task performed at the tank farm, the mean benzene air concentrations are below the current OSHA short-term exposure limit (5 ppm).

Benzene concentrations by time period

A number of tasks demonstrated a statistically significant decrease in benzene air concentrations after 1990 (Figure 3(b)). For example the blinding and breaking task at the reformer decreased from 3.3 ppm before 1990 to 0.81 ppm after 1990.

Discussion

Discussion of non-task results

The results presented in this manuscript represent a comprehensive analysis of workplace benzene air concentrations measured at four petroleum refineries in the US over the last 30 years. In general, concentrations for both non-task and task specific samples were consistent with results from other studies that have evaluated occupational benzene exposures in the petroleum industry (Buchet et al., 1984; CONCAWE, 1987, 1994; HEI, 1988; Nordlinder and Ramnas, 1987; Rappaport et al., 1987; Runion and Scott, 1985; Verma et al., 2001; Weaver et al., 1983). When comparing the results of this study to the industry-wide datasets, the average exposures at these four refineries are equal to or less than those reported in the literature despite the fact that this dataset was derived from a sampling program designed to target benzene handling activities. The average benzene air concentration in this dataset for all non-task samples is 0.21 ppm (during routine operations), compared to the arithmetic means in the existing literature, which range from 0.05 to 1.62 ppm, with an average of 0.22 ppm (Runion and Scott, 1985; Verma et al., 2001).

Analysis of the non-task benzene samples indicated that 57% had benzene air concentrations below the limit of detection (Table 3; Supplemental Table 1 (Available online at: http://tih.sagepub.com/content/by/supplemental-data)). Given the large number of samples in the dataset and the targeted nature of the sampling program, which tends to oversample job categories where direct contact with benzene containing streams is most likely, the low detection frequency is indicative of generally low concentrations of benzene in the air. Specifically, nearly 98% of the non-task sample results were less than 1 ppm, a finding consistent with an industry-wide study indicating that 95% of benzene results from air samples taken at several U.S. refineries were below 1 ppm (Runion and Scott, 1985).

Discussion of task results

The benzene air concentrations associated with the 24 task bins were largely undetectable, with only five bins (n>10) demonstrating detection frequencies of 50% or more (Table 4; Supplemental Table 2 (Available online at: http://tih.sagepub.com/content/by/supplemental-data)). Overall, the results from the analysis of the task-level data indicate that tasks that require opening of equipment containing liquid process streams, such as blinding and breaking, equipment cleaning and repair, and equipment preparation generally have higher air concentrations than those where direct contact is minimal (Table 4; Supplemental Table 2 (Available online at: http://tih.sagepub.com/content/by/supplemental-data)). These results reinforce the historic focus of the benzene exposure control program described earlier. Of the 3,768 task level samples, 4% had results greater than 5 ppm. In comparison, in a study of European refineries, 14% of the benzene air concentrations associated with the tasks conducted by refinery operators exceeded 5 ppm (CONCAWE, 1994).

Each task bin used in this analysis was created to characterize subsets of all tasks performed at the four refineries, with the intention to include in each task bin activities that have a similar exposure potential. As each job category is defined by the types of activities that an individual may perform, each task bin has only a few job titles associated with it. Nevertheless, with the exception of blinding and breaking and equipment cleaning and repair, there was no difference between job titles within each task bin, indicating that the tasks were the primary determinant of exposure.

Similar (i.e., low) exposures are expected throughout refinery process units during normal operations when the system is closed regardless of the amount of benzene present in the stream (Figure 2(a) to (d)). The analysis of the task bin by area further supports this concept, as it also indicated no statistically significant difference by area except for blinding and breaking. In addition, there was no meaningful difference from an industrial hygiene perspective across refineries for the most frequently sampled tasks (Figure 2(e) to (i)). However, as mentioned above, air concentrations may be higher when tasks that involve opening equipment (e.g., for maintenance work, blinding, sampling) are performed in areas where process streams contain higher concentrations of benzene (e.g., reformer, tank farm) (Table 4). In this case, area may play a role in potential exposure during a specific task. As an example, process technicians collecting samples in the reformer would be expected to have potentially higher benzene exposures than process technicians collecting samples in the lube extraction unit where benzene content in streams is much lower. The average exposure for process technicians collecting samples in the reformer compared to the lube extraction unit is 1.48 ppm (standard deviation, 5.6 ppm) versus 0.020 ppm (standard deviation, 0.014 ppm), respectively. Similarly, estimates show that the average air concentration for machinists performing the blinding/breaking task in the reformer is 2.41 ppm (standard deviation, 5.6 ppm), whereas the average exposure for machinists performing the same task in the alkylation unit was 0.030 ppm (standard deviation, 0.029 ppm). The large variability in benzene air concentrations at the reformer during these tasks supports the concept that in general, benzene air concentrations are low, but potential for episodic benzene air concentrations greater than 5 ppm can occur where atypical unit upsets or temporary equipment cannot be adequately prepared.

Discussion of exposure by time period

Post 1990 non-task sample results, on average, were less than 0.2 ppm and task samples, on average, were less than 0.5 ppm; these results are not surprising given the variety of controls that were put into place after the adoption of a series of regulations in the US to reduce benzene air emissions, including the Clean Air Act and the MACT standard (Maximum Achievable Control Technology). Closed, vented sampling systems (e.g., Dopak® sample systems), closed system draining, bleeders on piping where feasible, internal floating roofs (with specified seals), and other control measures were recommended and implemented across the ExxonMobil refineries. The analysis of air concentration before and after 1990 showed that for a number of job categories and task bins, values were significantly lower in the 1990 to 2007 time period compared to the 1977 to 1989 time period (Figure 3(a) and (b)). These results are consistent with expectations, given the general time period in which various process changes were implemented. While the facilities studied ranged in year of construction from 1902 to 1973, the above mentioned controls would have applied to all facilities regardless of age, and retro fits would have occurred with key regulatory milestones.

Discussion of targeted monitoring strategy

In addition to implementing process modifications designed to reduce benzene exposure in the workplace, ExxonMobil has established benzene programs and practices, which continually evolve to ensure employee exposures remain below exposure limits and to comply with the OSHA standards. According to the ExxonMobil monitoring strategy and standard industrial hygiene practice, air sampling for benzene has been focused to identify higher potential exposure areas or activities to verify control recommendations (typically respiratory protective equipment) for workers if needed. To this end, workers with potentially higher exposure jobs were targeted based on the process, the work and the work area. Quantitative measurements of exposure are targeted to assess tasks and activities with higher potential for exposure, or to reduce the uncertainty in exposure assessment results. Much of the exposure monitoring has historically been focused on activities or jobs where a worker(s) is working with a stream that contains a higher percentage of benzene (i.e. reformate), or performing a task with higher potential for benzene contact, rather than a worker(s) in an area of the refinery that does not contain any benzene (i.e. the methyl ethyl ketone (MEK) unit). Once an area, job, or task is well characterized and determined to be of low exposure potential, or acceptable controls have been implemented, collection of additional data for that area, job, or task becomes less intense, as part of a prioritized monitoring plan. As a result of this focused or targeted monitoring strategy, the majority of available benzene monitoring results was collected during tasks and activities with a greater likelihood of exposure to benzene, resulting in benzene air sampling data that over-represent workers and work activities with higher benzene exposures. This sampling approach is evident in the number of samples taken for each job, area, or task and is consistent across the four refineries included in this analysis. Those areas with process streams that contained the highest percentage of benzene were the most frequently sampled (Table 2); similarly, the jobs and tasks with the highest likelihood of contact with process streams containing benzene were most frequently sampled (Table 3 and 4).

Based on the targeted sampling approach used by the industrial hygienists at these refineries, the non-task sample averages calculated for each job category may not represent long-term (over the span of months or years) averages for all job titles. The average daily non-task results presented in this manuscript are expected to be generally representative of long-term averages for those job categories where individuals have regular contact with process streams (e.g., process technicians, and some workers performing maintenance tasks including pipefitter-welders, etc.). However, for those job categories where individuals do not have regular contact with process streams (e.g. instrument technicians, mobile equipment operators, and so on), the benzene air concentrations are more likely representative of unique activities performed on the sampling day (e.g., a task that is done one a month or once a quarter). Therefore, the daily averages presented here for certain job categories, may not be the representative of long-term averages.

Strengths and limitations of the study

This study provides analysis of a robust dataset of benzene air samples, and considers several factors: operational status of the refinery, area of the refinery, job title, and task performed. Of the studies available in the existing literature, none have attempted to consider all of these factors across multiple facilities in determining potential benzene exposure; rather, most of the literature has focused only on one variable, such as refinery area or job. A key strength of this study is that it highlights the impact of select operational influences and the need to consider these aspects in addition to statistics to ensure appropriate data grouping and interpretation of results. Furthermore, within the review of the data, an exhaustive independent review of the data was conducted to ensure data quality and accuracy with respect to original documentation.

The analysis by task is unique to this series of studies; other studies have focused primarily on long-term exposure estimates. Verma et al., 2001 summarized data from several studies evaluating benzene exposure to employees in petroleum industries, and explicitly recommend moving towards task-based exposure assessments as opposed to long-term time weighted average estimates for the petroleum industry (Verma et al., 2001).

While this study improves upon the currently available literature, it is not without limitations. Although these facilities have been actively involved in the assessment of worker exposures to benzene since the 1950s, only limited documentation of the results prior to 1976 were available. As a result, quantification of workers’ exposures prior to 1976 will require some extrapolation from the current dataset (Proctor et al., 2004). By combining air concentration data from four refineries, the sample number for each job category and task bin per year from 1976 to 2007 has increased; however, samples were not collected every year for each job category and task bin. Therefore, interpolation will be necessary in order to determine exposures during years when data were not collected.

While uniform cross refinery jobs, areas, and task were able to be created, certain jobs, areas, and tasks were only sampled at certain refineries. In addition, some job titles, tasks, and areas not routinely monitored are specific to certain refineries. Therefore, knowledge of ExxonMobil refineries is important for those attempting to undertake an exposure reconstruction or epidemiological study with this data.

For the sake of transparency, suspected outliers were included in this analysis. Depending on the use of these data, statistical outliers should be assessed and removed from the dataset where appropriate. In addition, the dataset should be examined for exposure data associated with a special or unusual event. For example, if one were to reconstruct the exposure of a worker who was a process technician at the Baytown hydrofiner in 1978, it may be appropriate to use the benzene air concentration data for that job collected during what appears to be an unusual event at the Baytown hydrofiner in 1978. Conversely, if the data are being used to describe typical operational exposures in petroleum hydrofining, the 1978 Baytown hydrofiner air concentration excursion data should likely be excluded. Lastly, respiratory protection factors or adjustments have not been applied to the measured air concentrations. Based on available documentation, respiratory protection is part of the standard work practice for tasks, and may need to be considered when using the data for exposure reconstruction, where data are intended to be reflective of exposure dose versus environmental concentration. In addition, biomonitoring data could be used to better characterize and assess overall exposure dose and source attribution.

Because of the targeted nature of the monitoring strategy used at these refineries, care must be taken when using the data presented in this analysis to estimate employee exposures to benzene. Since for some job categories, the non-task-specific daily averages may not accurately represent long-term averages, it is necessary to reconstruct these exposures on a case-by-case basis. This may require use of the task-based data, time-activity patterns and exposure frequencies to reconstruct daily exposures. Furthermore, by reconstructing an individual’s exposure on a case-by-case basis, considerations can be made, if appropriate, for respirator use. These data will also be useful for epidemiology studies. As task performed and time period have emerged as key determinants of exposure, work histories can carefully be matched with the appropriate exposure data.

The distribution of data for the most frequently sampled job titles and task bins across these four facilities demonstrated that variability exists between refineries. In addition, some statistically significant differences were observed (p < 0.05). However, the differences observed were not meaningful from an industrial hygiene stand point in that the averages for each refinery were all well below 1 ppm and 5 ppm for non-task and task samples, respectively.

By combining 30 years of exposure data from four US refineries, we have created a robust dataset that should be useful for application to future epidemiology studies or worker exposure reconstruction. Although air concentrations vary across and within refineries by area of work performed, job title, and task, certain trends became apparent: (1) the low detection frequency and low average benzene air concentrations support the hypothesis that systems are often closed in the refinery, (2) the majority of samples were collected in areas of the refinery with process streams containing higher percentages of benzene, indicative of the targeted sampling approach used by Exxon Mobil industrial hygienists, (3) the jobs and tasks most often monitored are those where the potential for exposure to benzene exists, (4) time period and task performed have emerged as key determinants of exposure, (5) and lastly while the specific task performed is a major determinant of exposure, it is clear that the benzene content of the process stream also plays a role during tasks when the system is open.

Conclusion

The data presented here indicate that the benzene air concentrations at four ExxonMobil refineries in the US are generally low compared to the contemporaneous OEL for both non-task and task-based sampling events. The combined analysis also helps support the hypothesis that there are certain critical determinants of worker benzene exposure. Pre- and post-1990 data analysis shows a reduction in overall benzene air concentrations. Process stream benzene content as well as the performance of specific tasks are also key factors. As noted in the discussion of task results, it was observed that air concentrations may be higher when tasks that involve opening equipment are performed in areas where process streams contain higher concentrations of benzene.

This combined dataset will be particularly useful for conducting future epidemiological studies for refinery workers. When considering these data for exposure reconstruction, it is especially important to bear in mind the nature of the samples analyzed in this dataset, which were primarily collected using a targeted strategy. As such, these data are likely to represent the upper tail of benzene air concentrations at the refinery, rather than air concentrations representative of typical exposures. In addition, respiratory protection factors or adjustments have not been applied to the measured air concentrations. This study demonstrates the necessity of analyzing refinery benzene exposures on the task level, and is useful for understanding which activities drive refinery worker exposures to benzene.

Supplementary Material

Acknowledgments

We thank Paul Scott and Jennifer Bare of Cardno ChemRisk for their assistance with the statistical analysis.

Footnotes

Funding: The author(s) disclosed receipt of the following financial support for the research, authorship, and/or publication of this article: This work was funded by ExxonMobil, a firm that has been involved in the study of benzene for several decades. At least two of the authors have served or are likely to serve as expert witnesses for ExxonMobil on matters relating to industrial hygiene, exposure assessment, risk assessment, or toxicological issues related to benzene.

References

- Armstrong TW, Pearlman ED, Schnatter AR, et al. (1996) Retrospective benzene and total hydrocarbon exposure assessment for a petroleum marketing and distribution worker epidemiology study. American Industrial Hygiene Association Journal 57: 333–343. [DOI] [PubMed] [Google Scholar]

- Baccarelli A, Pfeiffer R, Consonni D, et al. (2005) Handling of dioxin measurement data in the presence of non-detectable values: overview of available methods and their application in Seveso chloracne study. Chemosphere 60: 898–906. [DOI] [PubMed] [Google Scholar]

- Buchet JP, Van Eyken J, Lauwerys R. (1984) The evaluation of the exposure of benzene for the workers that are related to or in charge of the oil refinery (original in French). Cahiers de Medecine de Travail Cahiers Voor Arberdsgeneeskunde 21: 25–27. [Google Scholar]

- CONCAWE (1987) A Survey of Exposures to Gasoline Vapour. The Hague: Oil Companies European Organization for Environment, Health and Safety (CONCAWE; ). [Google Scholar]

- CONCAWE (1994) Review of European Oil Industry Benzene Exposure Data (1986-1992). Brussels: Oil Companies European Organization for Environment, Health and Safety (CONCAWE; ). [Google Scholar]

- Fishbein L. (1988) Benzene: uses, occurrence and exposure. IARC Scientific Publication 85: 67–96. [PubMed] [Google Scholar]

- Gaffney SH, Burns AM, Kreider M, et al. (2010) Occupational exposure to benzene at the ExxonMobil refinery in Beaumont TX (1976-2007). International Journal of Hygiene and Environmental Health 213: 285–301. [DOI] [PubMed] [Google Scholar]

- Gaffney SH, Panko JM, Unice KM, et al. (2011) Occupational exposure to benzene at the ExxonMobil Refinery in Baytown, TX (1978-2006). Journal of Exposure Science and Environmental Epidemiology 21: 169–185. [DOI] [PubMed] [Google Scholar]

- Glass DC, Adams GG, Manuell RW, et al. (2000) Retrospective exposure assessment for benzene in the Australian petroleum industry. Annals of Occupational Hygiene 44(4): 301–320. [PubMed] [Google Scholar]

- Glass DC, Gray CN, Adams GG, et al. (2001) Validation of exposure estimation for benzene in the Australian petroleum industry. Toxicology and Industrial Health 17(4): 113–127. [DOI] [PubMed] [Google Scholar]

- Glass DC, Gray CN, Jolley DJ, et al. (2005) Health Watch exposure estimates: do they underestimate benzene exposure? Chemico-Biological Interact 153-154: 23–32. [DOI] [PubMed] [Google Scholar]

- HEI (1988) Gasoline Vapor Exposure and Human Cancer: Evaluation of Existing Scientific Information and Recommendations for Future Research. Cambridge: Health Effects Institute (HEI; ). [Google Scholar]

- Helsel DR. (2005) More than obvious: better methods for interpreting nondetect data. Environmental Science and Technology 39: 419A–423A. [DOI] [PubMed] [Google Scholar]

- Helsel DR, Cohn T. (1988) Estimation of descriptive statistics for multiply censored water quality data. Water Resoures Research 24: 1997–2004. [Google Scholar]

- Hewett P. (2007) User Guide for IH DataAnalyst.

- Huybrechts T, Thas O, Dewulf J, et al. (2002) How to estimate moments and quantiles of environmental data sets with non-detected observations? A case study on volatile organic compounds in marine water samples. Journal of Chromatography 975: 123–133. [DOI] [PubMed] [Google Scholar]

- Ignacio JS, Bullock WH. (2006) A Strategy for Assessing and Managing Occupational Exposures. 3rd ed Fairfax: AIHA Press. [Google Scholar]

- Kreider M, Unice KM, Panko JM, et al. (2010) Benzene exposure in refinery workers: ExxonMobil Joliet, Illinois, USA (1977-2006). Toxicology and Industrial Health 26(10): 671–690. [DOI] [PubMed] [Google Scholar]

- Lubin JH, Colt JS, Camann D, et al. (2004) Epidemiologic evaluation of measurement data in the presence of detection limits. Environmental Health Perspectives 112(17): 1691–1696. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Neter J, Wasserman W, Kutner MH. (1990) Applied Linear Statistical Models. 3rd ed Burr Ridge: Irwin. [Google Scholar]

- Nordlinder R, Ramnas O. (1987) Exposure to benzene at different work places in Sweden. Annals of Occupupational Hygiene 31(3): 345–355. [DOI] [PubMed] [Google Scholar]

- OSHA (1987) 29 CFR 1910.1028: Benzene.

- Panko JM, Gaffney SH, Burns AM, et al. (2009) Occupational exposure to benzene at the ExxonMobil Refinery at Baton Rouge, Lousiana (1977-2005). Journal of Occupational and Environmental Hygiene 6(9): 517–529. [DOI] [PubMed] [Google Scholar]

- Proctor DM, Panko JM, Liebig EW, et al. (2004) Estimating historical occupational exposure to airborne hexavalent chromium in a chromate production plant: 1940--1972. Journal of Occupational and Environmental Hygiene 1(11): 752–767. [DOI] [PubMed] [Google Scholar]

- Rappaport SM, Selvin S, Waters MA. (1987) Exposures to hydrocarbon components of gasoline in the petroleum industry. Applied Industrial Hygiene 2(4): 148–154. [Google Scholar]

- Runion HE, Scott LM. (1985) Benzene exposure in the United States 1978–1983: an overview. American Journal of Industrial Medicine 7(5-6): 385–393. [DOI] [PubMed] [Google Scholar]

- USEPA (1989) 40 CFR 61 Subpart FF: National Emission Standards for Benzene in Waste Operations.

- USEPA (1998, June) Locating and Estimating Air Emissions from Sources of Benzene. EPA-454/R-98-011. Research Triangle Park, NC: Office of Air Quality Planning and Standards, U.S. Environmental Protection Agency. [Google Scholar]

- USEPA (2007) Statistical Softward ProUCL 4.0 for Environmental Applications for Data Sets with and without Nondetect Observations In: Technical Support Center for Monitoring and Site Characterization. [Google Scholar]

- van Wijngaarden E, Stewart PA. (2003) Critical literature review of determinants and levels of occupational benzene exposure for United States community-based case-control studies. Applied Occupational Environmental Hygiene 18(9): 678–693. [DOI] [PubMed] [Google Scholar]

- Verma DK, des Tombe K. (1999) Measurement of benzene in the workplace and its evolution process. Part 1. Overview, history and past mthods. American Industrial Hygiene Association Journal 60(1): 38–47. [DOI] [PubMed] [Google Scholar]

- Verma DK, Johnson DM, Shaw ML, et al. (2001) Benzene and total hydrocarbons exposures in the downstream petroleum industries. American Industrial Hygiene Association Journal 62(2): 176–194. [DOI] [PubMed] [Google Scholar]

- Weaver NK, Gibson RL, Smith CW. (1983) Occupational exposure to benzene in the petroleum and petrochemical industries In: MA Mehlman. (ed) Occupational Exposure to Benzene. Princeton: Princeton Scientific Publishers, pp. 63–73. [Google Scholar]

- WHO (1993) Environmental Health Criteria 150: Benzene. Geneva: IPCS INCHEM, International Programme on Chemical Safety. [Google Scholar]

- Widner TE, Gaffney SH, Panko JM, et al. (2011) Airborne concentrations of benzene for dock workers at the ExxonMobil refinery and chemical plant, Baton Rouge, Louisiana (1977–2005). Scandinavian Journal of Work and Environmental Health 37(2): 147–158. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.