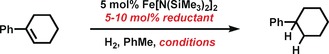

Table 1.

Selected optimization experiments.[a]

| Entry | Reductant (mol %) | Conditions | Yield [%][b] |

|---|---|---|---|

| 1 | EtMgCl (10) | 5 bar H2, 40 °C, 18 h | 5 (9) |

| 2 | Zn (10) | as entry 1 | <1 (1) |

| 3 | – | 5 bar H2, 150 °C, 18 h | 1 (1) |

| 4 | NaBH4 (5) | as entry 1 | 99 (99) |

| 5 | NaBH4 (5) | 1.3 bar H2, 20 °C, 3 h | 1 (2) |

| 6 | LiAlH4 (5) | as entry 4 | 99 (99) |

| 7 | Me3Al (10) | 1.3 bar H2, 20 °C, 0.5 h | 90 (98) |

| 8 | iBu3Al (10) | as entry 7 | 93 (99) |

| 9 | i Bu2AlH (10) | as entry 7 | 100 (100) |

| 10 | iBu2AlH (10) | FeCl2, HN(TMS)2, nBuLi[d] | 98 (99) |

| 11 | – | as entry 7 | <1 (1) |

| 12 | iBu2AlH (10) | as entry 7, FeCl2 [c] | <1 (1) |

[a] Conditions: 0.2 mmol alkene, 0.5 m in toluene, 5 mol % Fe[N(SiMe3)2]2, reductant, H2. [b] Yields determined by quantitative GC‐FID vs. internal n‐pentadecane. [c] 5 mol % FeCl2 instead of Fe(hmds)2. [d] 5 mol % FeCl2, 10 mol % HN(SiMe3)2, 10 mol % n‐butyl lithium (1.6 m in PhMe) instead of Fe(hmds)2.