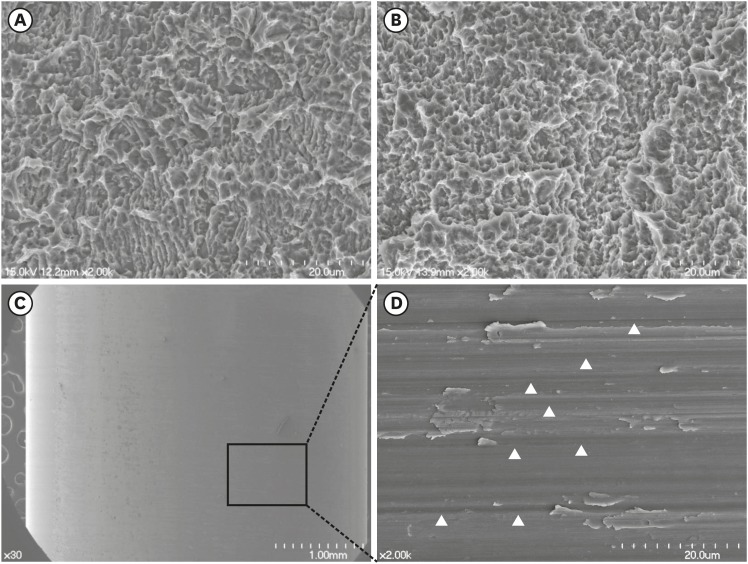

Figure 2.

FE-SEM of the modSLA and SLA implants and the Ti tube. (A and B) FE-SEM images of the modSLA (A) and SLA (B) surfaces. Both implant types had been blasted with large-grit sand and acid-etched. The modSLA implant was further modified by being rinsed under nitrogen protection and then sealed in glass tubes containing isotonic NaCl. This procedure was conducted to increase the hydrophilicity of the implant. The surfaces exhibited similar micro-topographical features. The procedure intended to increase hydrophilicity had little effect on the modSLA surface topography. (C) FE-SEM images of the Ti tube. The left image shows a machined surface consisting of grade 4 commercially pure Ti. The right image shows a magnification of the left-hand FE-SEM image. It depicts many machined grooves that were etched by computer numerical control milling (white arrowheads). The bars in the left (A, B, C) and right (C) images indicate 20 μm, 20 μm, 1 mm, and 20 μm, respectively.

FE-SEM: field emission scanning electron microscopy, modSLA: modified sandblasted and acid-etched, SLA: sandblasted and acid-etched, Ti: titanium, NaCl: sodium chloride.