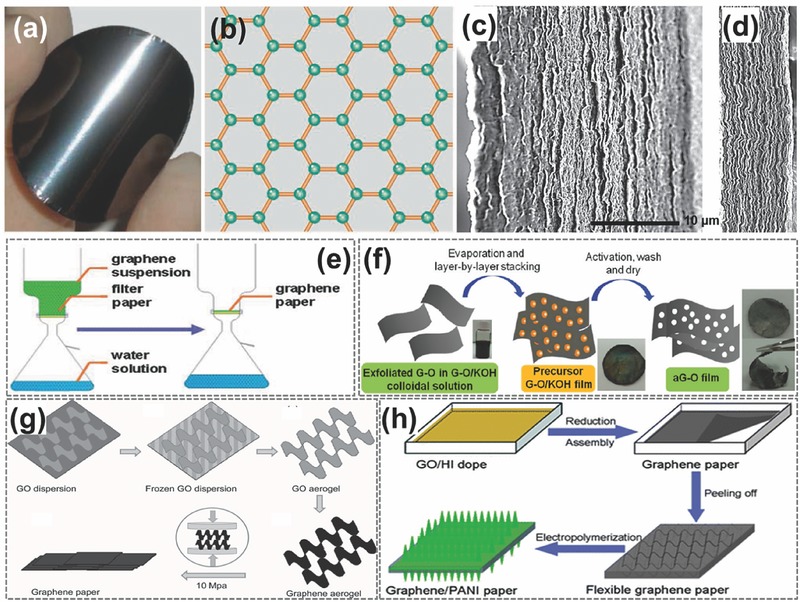

Figure 5.

Schematic diagrams of four approaches for making graphene paper electrodes. a) Simple structure, great potential. Shiny and flexible graphene paper is formed by controlled restacking of graphene sheets. b) In graphene, carbon atoms (green dots) are bonded together through sp2 hybridization (orange lines). Reproduced with permission.50 Copyright 2008, American Association for the Advancement of Science. c,d) SEM images of cross sections of the obtained liquid electrolyte‐mediated chemically converted graphene films containing (c) 78.9 volume percent (vol. %) and (d) 27.2 vol. % of H2SO4, respectively, corresponding to ρ = 0.42 g cm−3 and ρ = 1.33 g cm−3. Reproduced with permission.123 Copyright 2013, American Association for the Advancement of Science. e) Graphene paper was produced via the vacuum filtration of graphene dispersion. Reproduced with permission.132 Copyright 2013, American Chemical Society. f) Schematic illustration showing the experimental steps of activated reduced graphene oxide film. Reproduced with permission.133 Copyright 2012, American Chemical Society. g) Illustration of the formation process of graphene paper. Step 1, GO aqueous dispersion. Step 2) GO dispersion frozen at −50 °C. Step 3) GO aerogel obtained by freeze drying. Step 4) Under vacuum. Step 5) Graphene aerogel obtained by treating Go aerogel at 200 °C in air. Step 6) Mechanical pressing of the graphene aerogel to form graphene paper. Reproduced with permission.134 h) Schematic illustrations of the formation process of graphene–PANI paper. Reproduced with permission.135 Copyright 2013, Royal Society of Chemistry.