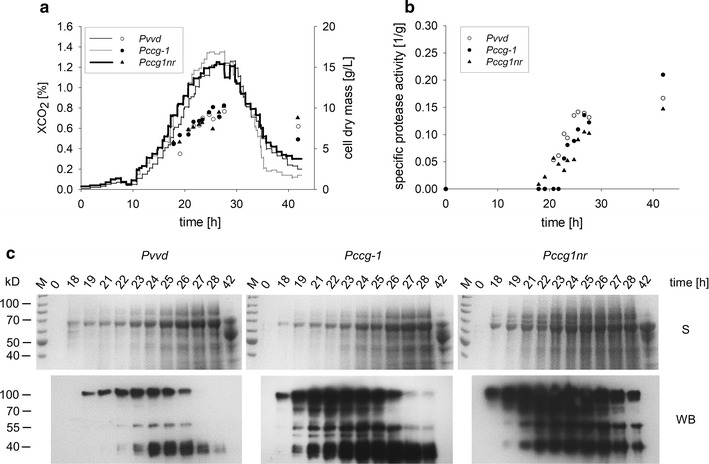

Fig. 5.

Process optimization results in the production of significant amounts of heterologous protein. a Growth characteristics (XCO2: graph; dry mass: data points) and b protease activity of production strains with different promoters under optimized process conditions. Cultivation was conducted in a controlled 1 L bioreactor system in minimal Bird medium with maltose as the sole carbon source at 30 °C. The pH value was controlled at pH 6.5 by the addition of sodium hydroxide throughout cultivation. Protease activity was determined as stated above. The employed strains were Pvvd (DHN-201: Pvvd-glat-ht186-13×myc, exo-1, ∆vib-1, ∆vvd), Pccg-1 (DHN-172: Pccg-1-glat-ht186-13×myc, exo-1, ∆vib-1, ∆vvd) and Pccg1nr (DHN-250: Pccg1nr-glat-ht186-13×myc, exo-1, ∆vib-1, ∆vvd). c Production of the heterologous fusion protein. Concentrated proteins from the supernatant were separated via SDS-PAGE (S) and the product was detected after Western blot transfer (WB). The signal was developed with electrochemiluminescence (development time of 1 s)