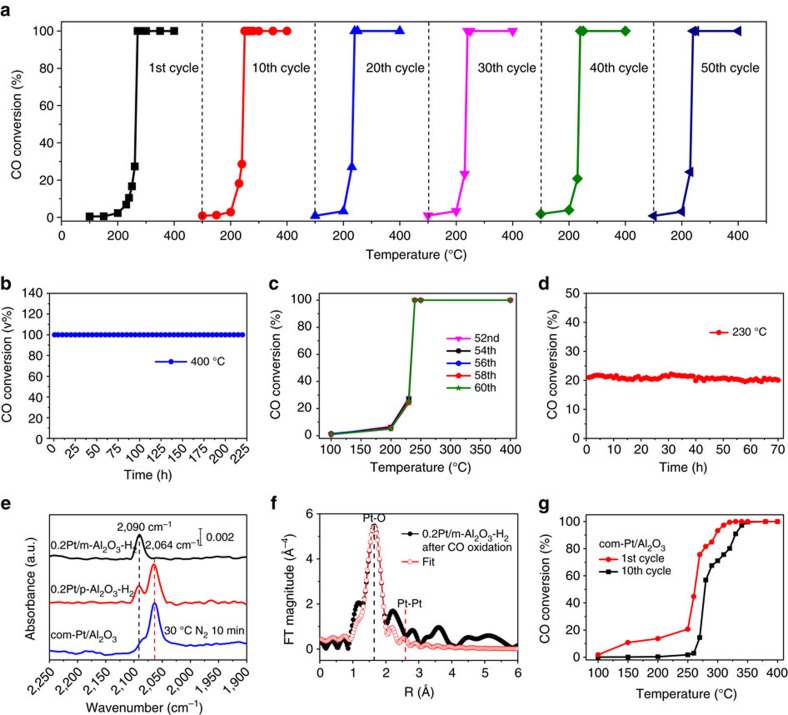

Figure 5. Evaluation of 0.2Pt/m-Al2O3-H2 and control catalysts in CO oxidation.

(a) Conversion of CO from 100 to 400 °C with 1st–50th cycles, (b) maintained at 400 °C for 220 h, (c) another ten cycles from 100 to 400 °C, (d) maintained at 230 °C for 70 h after 60 cycles, (e) IR spectra for 0.2Pt/m-Al2O3-H2 after the CO oxidation sequence as shown in a–d, 0.2Pt/p-Al2O3-H2 after 14 cycles CO oxidation and commercial Pt/Al2O3 catalysts after ten cycles CO oxidation, (f) the k3-weighted Fourier transform spectrum derived from EXAFS for 0.2Pt/m-Al2O3-H2 after the CO oxidation sequence as shown in a–d, (g) conversion of CO from 100 to 400 °C in the 1st and the 10th cycles over commercial Pt/Al2O3 (named com-Pt/Al2O3). 2.5 vol% CO, 2.5 vol% O2 and balance Ar was allowed to pass through the reactor at a flow rate of 80 ml min−1.