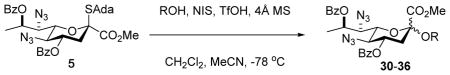

Table 1.

Glycosylation Reactions

| ||||

|---|---|---|---|---|

| Entry | Acceptor | Product | % Yield, α:β ratio | 3JCH (Hz) |

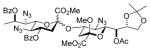

| 1 | BnOH |

30 |

96%, α-only | 30: 7.2 |

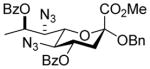

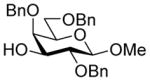

| 2 |

27 |

31αβ |

87%, 6.7:1 | 31α: 6.4 |

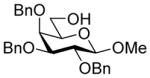

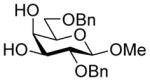

| 3 |

26 |

32α,β |

82%, 4.4:1 | 32α: 6.9 |

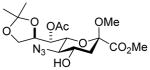

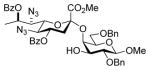

| 4 |

28 |

33α,β |

75%, a4.5:1 |

33α: 7.2 33β: 0 |

| 5 |

29 |

34α,β |

88%, 34α:34β:35α= 4.7:1:0.9 | 34α: 7.0 |

35 |

35α: 6,3 | |||

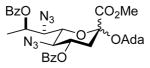

| 6 | 1-adamantanol |

36α,β |

73%, 4.2:1 | 36α: 5.7 |

Glycosylation gave an 84% yield of an inseparable 4.5:1 α:β mixture of the disaccharides, which was saponified to give the products 33α and 33β.