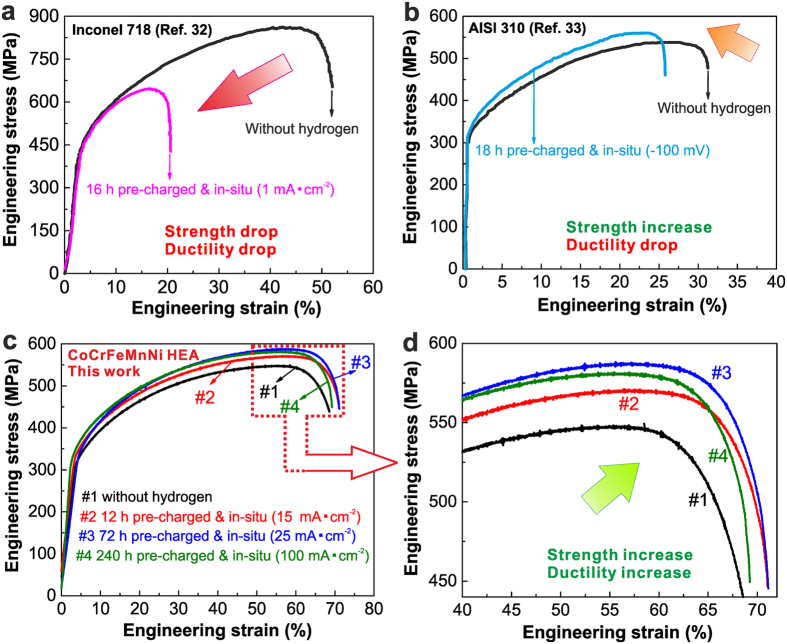

Figure 2.

Tensile deformation behavior of different metals including the CoCrFeMnNi HEA under various in-situ hydrogen charging conditions. (a) Engineering stress-strain curves of nickel-based alloy Inconel 718 (56Ni-18Fe-18Cr-5Nb-3Mo) with and without hydrogen (16 h pre-charged and in-situ tested at 1 mA·cm−2 in 3 wt.% NaCl solution, strain rate of 1 × 10−4 s−1, data taken from ref. 32). (b) Engineering stress-strain curves of AISI 310 stainless steel (55Fe-25Cr-20Ni) with and without hydrogen (18 h pre-charged and in-situ tested at −100 mV in 0.5 M H2SO4 solution, strain rate of 1 × 10−4 s−1, data taken from ref. 33). (c) Engineering stress-strain curves of CoCrFeMnNi HEA under various in-situ hydrogen charging conditions (Supplementary Fig. 1) at a quasistatic strain rate of 1 × 10−4 s−1. Three samples were tested for each hydrogen charging condition. (d) Zoom-in image revealing the joint increases in ultimate tensile strength and elongation for the CoCrFeMnNi HEA. Average values of the ultimate tensile strength and total elongation as well as the corresponding standard deviations are summarized in the supplementary Table 1.