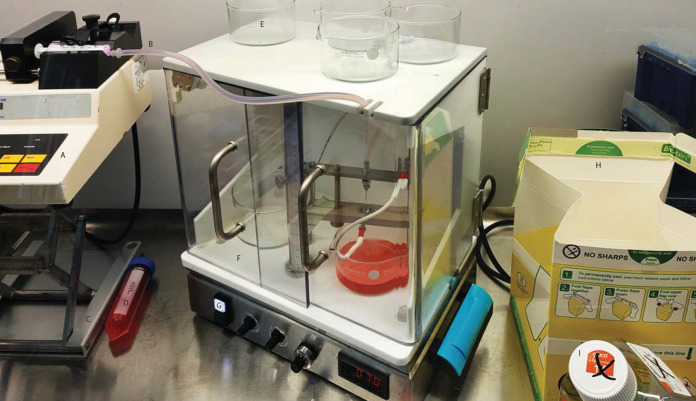

Figure 3. Biolelectrospraying microspheres.

Matrix in syringe is injected to the bioelectrosprying machine and microspheres are formed. A syringe filled with matrix was set up on syringe pump (A) so that it will inject the matrix into silicon tube (B) connected to the electrostatic bead generator. The syringe driver is sitting on jack (C) for height adjustment. E. Unused crystalizing glass beakers on the roof of the bioelectrospray machine; F. Housing with doors to enclose the electrostatic bead generator; G. High-voltage switch on/off (white, on/green, off) which is left of potentiometers for optional peristaltic pump, agitator speed and voltage on electrode. Voltage indicator displaying 7.0 kV. Biobin (H) and old media bottle (I) containing surfanios (10%) for discarding biohazardous waste.