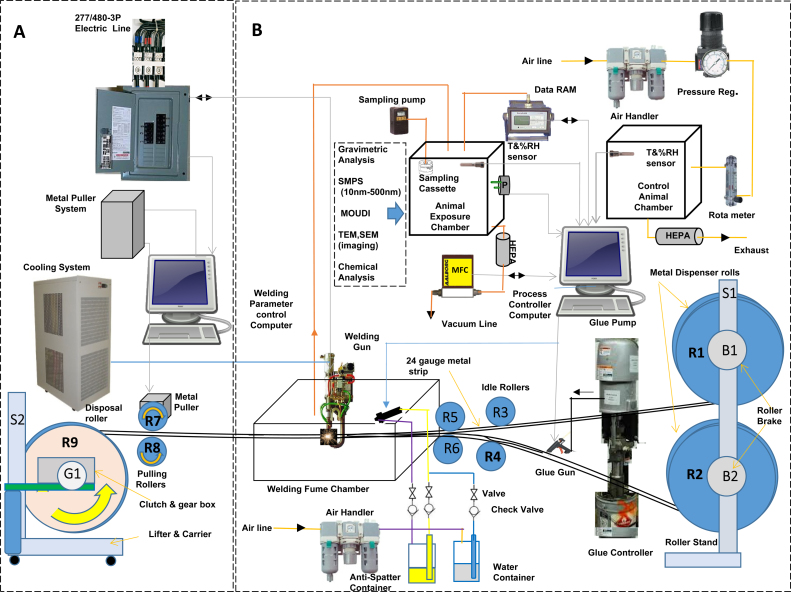

Fig. 1.

Diagram of the resistance spot welding fume generation and exposure system (adapted from Afshari et al., 2014). The system is divided into separated areas: (A) enclosed control room with the welding computer controller, the sheet metal puller system controller, electric power supply, and the spot welding gun cooling system; (B) resistance spot welding gun, air-tight welding fume chamber, sheet metal pulling system (sheet metal rolls and assorted rollers), anti-spatter spray system, glue pump and gun dispenser system, and animal exposure chambers for control and spot welding fume-exposed animals with assorted aerosol characterization devices. Abbreviations: DataRam = real-time aerosol monitor; MOUDI = Micro-Orifice Uniform Deposit Impactor; SEM = scanning electron microscopy; TEM = transmission electron microscopy; T = temperature; RH = relative humidity; SMPS = scanning mobility particle sizer; MFC = mass flow controller.