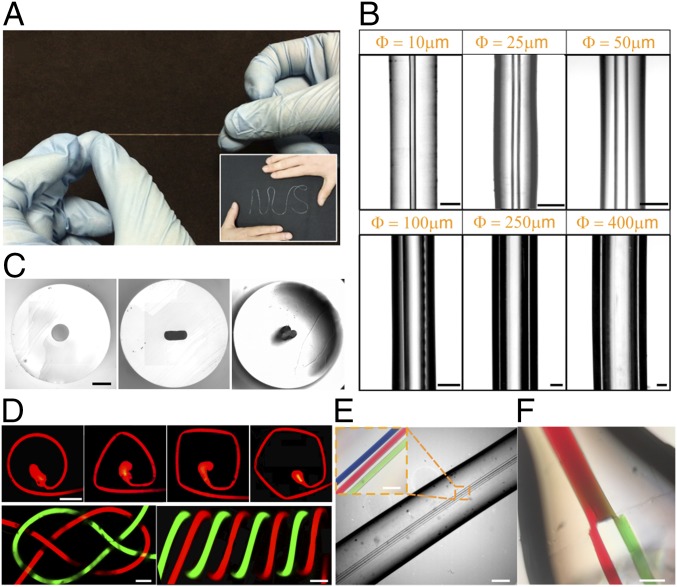

Fig. 2.

Fabrication of elastomeric microtubes. (A) Photograph of elastomeric microtube, demonstrating its flexibility and stretchability. (Inset) A microtube of over 30 cm, patterned to form the term “NUS.” (B) Images of PDMS microtubes with circular cross-sections with different IDs (side view, IDs are indicated by the orange text). (Scale bars: 30 μm for ID (Φ) = 10 μm, 75 μm for Φ = 25 μm, and 100 μm for the rest.) (C) Transverse planes of PDMS tubes with cross-sectional shapes of (Left) circle, (Center) rectangle, and (Right) club. (Scale bar: 250 μm.) (D) Microchannels of various 2D and 3D geometries created by winding the PDMS microtubes. (Top) Fluorescent images of 2D microchannels in (Left) circular, (Center Left) rectangular, (Center Right) square and (Right) pentagonal shapes. (Scale bar: 400 µm.) (Bottom) Optical micrographs of 3D microstructures (ID = 50 μm) in the shape of (Left) a Carrick bend knot and (Right) a double helical. (Scale bar: 150 μm.) (E) Microtube with multiple lumens. (Inset) Colored dyes within the microchannels. (Scale bars: 400 μm and, for Inset, 150 μm.) (F) Microtube with a bifurcated microchannel: two smaller channels merging into one main channel. (Scale bar: 200 μm.)