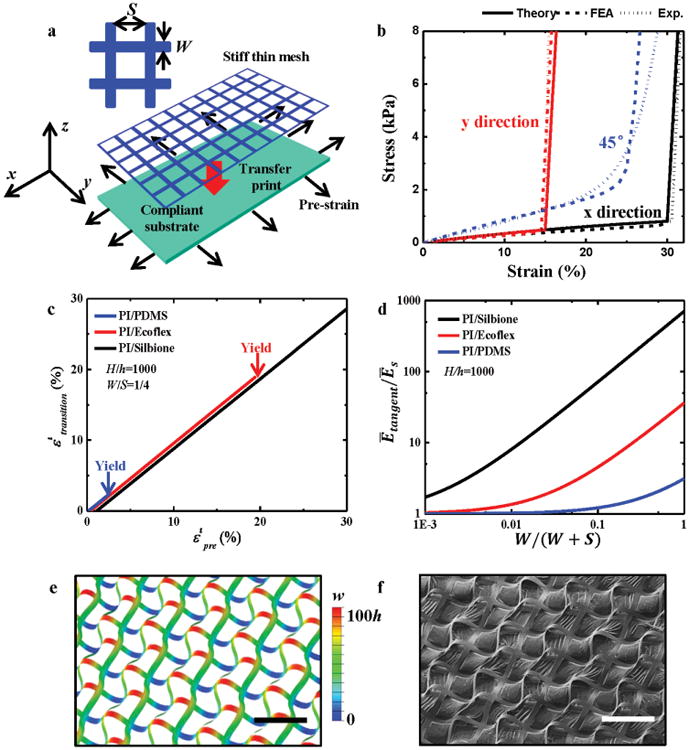

Figure 3.

a) Schematic illustrations of the fabrication process that uses biaxial stretching. b) Stress-–strain curves for x-, y-, and 45°-stretching of 1 μm-thick PI mesh (width W = 0.1 mm and spacing S = 0.4 mm) on 1 mm-thick Silbione substrate subjected to prestrains of and . c) The transition strain versus the prestrain for the PI mesh on several substrates with thickness ratio H/h = 1000 and W/S = 1/4. d) The tangent modulus normalized by the substrate modulus, Ētangent/Ēs, versus (W/(W + S)) for PI mesh on several substrates with thickness ratio H/h = 1000. e,f) Numerical results and optical images (scale bar, 200 μm) of morphology and out-of-plane displacement for 1 μm-thick PI mesh (width W = 0.1 mm and spacing S = 0.4 mm) on 1 mm-thick Silbione substrate subjected to prestrains of and .