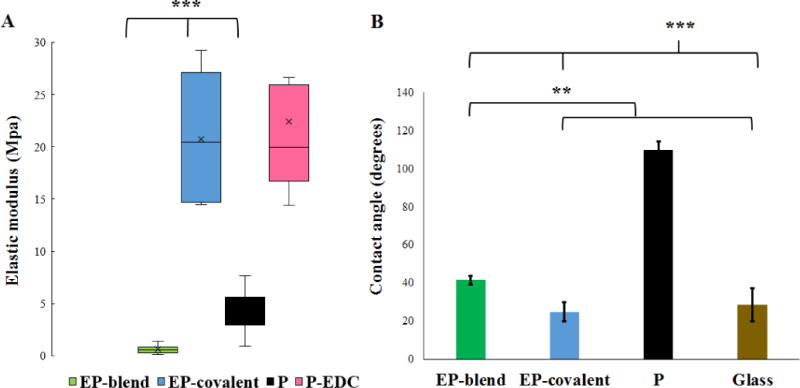

Figure 4.

Elastin improves the mechanical compliance and hydrophilicity of the nanofiber scaffolds. A- AFM mechanical characterization of the nanofiber scaffolds. Elastin functionalization by blend electrospinning conferred elasticity to the nanofiber scaffolds. EP-blend nanofibers show the smallest Young’s modulus at 0.59 ± 0.356 MPa as compared to 20.72 ± 5.978 MPa for EP-covalent, 4.29 ± 1.789 MPa for P and 20.4 ± 8.6 MPa for P-EDC. EP-blend, EP-covalent and P are significantly different from each other, while P-EDC and EP-covalent are not significantly different. B- Elastin functionalization and inclusion in the electrospun fibers by either blend electrospinning (EP-blend) or covalent conjugation (EP-covalent) significantly increases the wettability of the nanofiber scaffolds as indicated by the decrease in contact angle measurements. Contact angle measurement results are presented as mean ± SD; 42 ± 2.36°, 25 ± 5.25°, 110 ± 4.56°, 25.25 ± 4.1° for EP-blend, EP-covalent, P and glass, respectively. ANOVA with Bonferroni’s post-test; *p < 0.05, **p < 0.01, ***p < 0.001. P-EDC, PLGA fibers treated with EDC chemistry only without adding elastin.