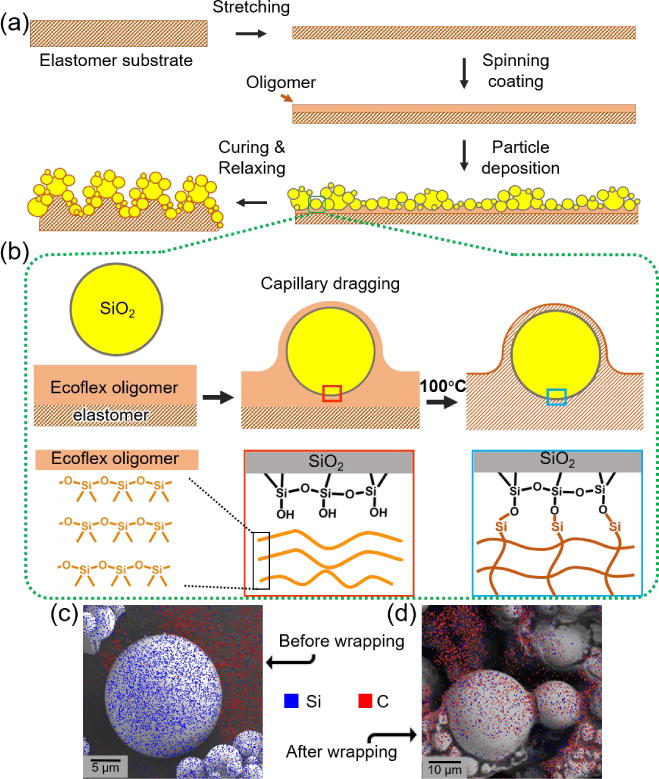

Fig. 2.

Schematics showing the fabrication and mechanism of the silicone elastomer/silica microparticle superhydrophobic surface. (a) A crosslinked silicone elastomer (Ecoflex) membrane is firstly stretched and spin-coated with a second layer of silicone oligomer. Silica microparticles are then deposited onto the silicone oligomer followed by curing at 100 °C. (b) As soon as the silica microparticles contact the silicone oligomers, the microparticles will be encapsulated by the oligomer via capillary dragging. At an elevated temperature of 100 °C, some Si-O backbones of the silicone oligomer break and bond with the hydroxyl group hanging outside of silica microparticles, forming stable chemical bonding. (c–d) EDX element mapping of the silica microparticles before and after encapsulated by the silicone elastomer. While large amount of carbon element could be detected on top of the silica microparticles after encapsulation (d), there were only negligible carbon signals on top of silica microparticles before the encapsulation(c).