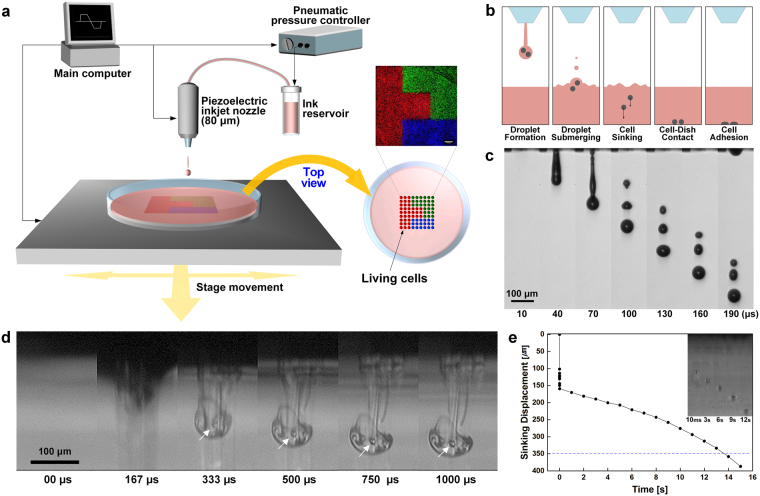

Figure 1.

Direct inkjet cell printing system and process. (a) Schematic of the apparatus used for direct inkjet cell patterning with a 3-axis controllable piezoelectric inkjet printing system. Cell-laden ink is printed from an ink reservoir through an 80-µm piezoelectric inkjet nozzle onto a liquid-filled cell culture dish. A computer controls the stand-off distance by adjusting the movement of the nozzle in the z direction and pattern design by adjusting the movement of the stage in the x and y directions. (b) Schematic illustration of the process used to pattern cells in a liquid-filled plate. A cell-laden drop is ejected from an inkjet nozzle, submerged in liquid substrate, and then cells in the drop sink, contact, and adhere to the bottom of the plate, where they remain on the printed position. (c) High-speed stroboscopic images of the jetting of a cell-laden drop were obtained with a CCD camera and a spark flash light at 30-µs intervals. (d) High-speed cinematographic images of sinking cells after a drop was impinged into a liquid-filled substrate. Images of a drop submerging and the cell sinking in a liquid medium were obtained at a rate of 12,000 frames per second using high-speed imaging. For visualization, the cell culture medium bath was replaced with 99% ethanol. White arrows indicate living cells sinking under the liquid pool after drop impact. (e) Tracking the displacement of sinking cells at different time intervals. The displacement of sinking cells was measured 10 times. The blue dashed line indicates the optimized depth (~350 µm) of the cell culture medium used to print cell patterns. Images shown in the upper right panel are representative images of sinking cells captured at each time point.