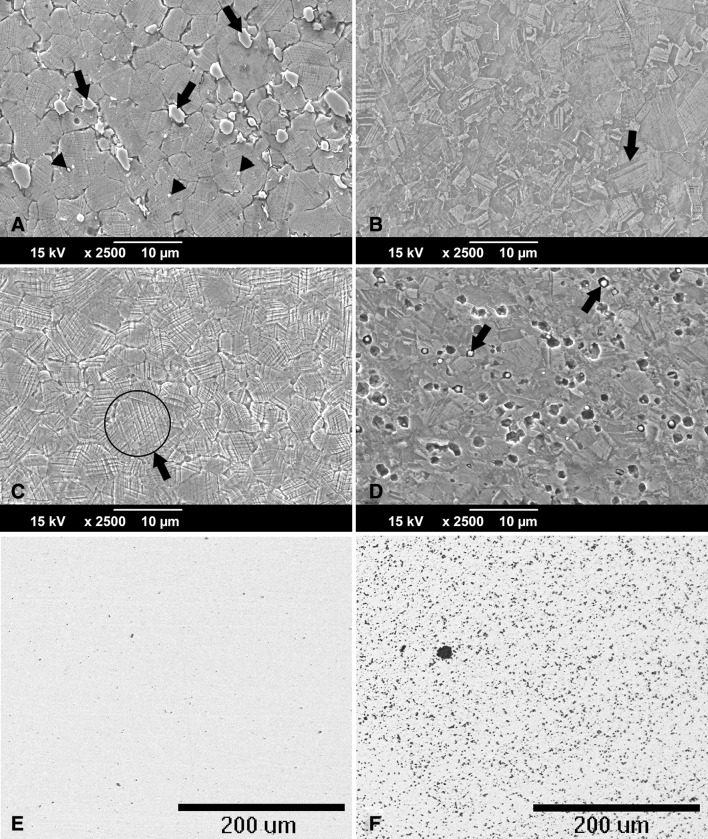

Fig. 9A–F.

Typical microstructure for all wrought alloys visualized through chemical etching: (A) HA-1: chromium carbides (arrows) and Mo-rich hard phases (arrow heads) are typically embedded within the matrix; (B) HA-2: typical grain structure with numerous twin boundaries (arrow); (C) HA-3: typical grain structure but with a high concentration of slip band reliefs (eg, as marked by arrow; (D) SA-4: fine grain size with fine Mo- and Si-rich hard phases embedded within the matrix (arrows) and some local pits presumably caused by hard phases detachment; (E) typical hard phase fraction (stained black) for Type 1 (< 1% hard phases) and (F) Type 2 (1%-5% hard phases) wrought alloy.