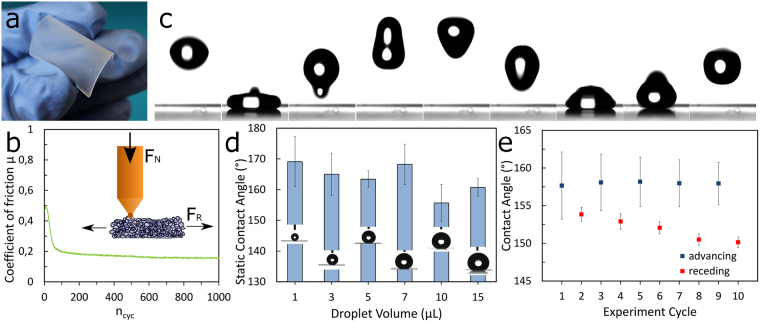

Figure 2.

Characterization of Fluoropor bulk nano-/microstructured polymer foam. (a) Fluoropor is a soft material and a substrate of 820 µm thickness is very flexible. (b) The wear resistance of Fluoropor was measured using a tribometer (schematic inset). After a break-in phase of ~50 cycles, a coefficient of friction of µ = 0.2 was determined (µ = FR/FN). (c) A 5 µL droplet of water bounces off a Fluoropor surface (time passed between frame 1 and frame 9: approximately 2.6 s). (d) The static contact angle of Fluoropor shows little variation at various droplet volumes and was determined to be an average of 163.7 ± 6.8°. (e) Advancing and receding contact angle measurements of Fluoropor gave 158.0 ± 7.9° and 151.9 ± 1.9°, respectively. The receding contact angle decreases due to evaporation of the droplet over time.