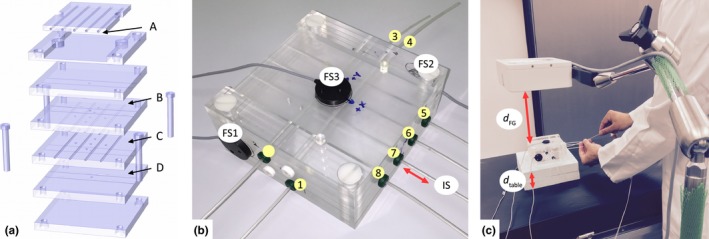

Figure 1.

(a) Exploded view drawing of our quality cross‐check phantom (Section 2.B) made out of transparent PMMA plates designed for position checks of cables with an active source (A) and precise guiding of catheters at different heights and orientations (B‐D). Several spherical air pockets can be used for image‐based QA and as landmarks for registration, e.g. with CT‐images of the phantom. (b) Picture of the phantom (120 × 120 × 60 mm3) with plastic catheters (i = 1, …, 8), three fixed fiducial sensors (FS) and an implant sensor (IS) in catheter (i = 7). (c) Measurement setup on the HDR treatment table. The distances d table and dFG were varied to study their influence on precision and accuracy.