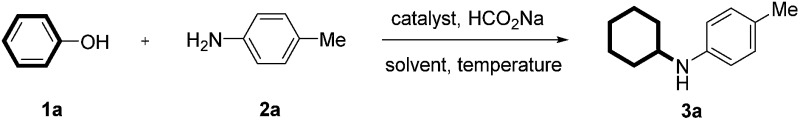

Table 1. Optimization of reaction conditions for cyclohexylation of p-toluidine with phenol a .

| ||||

| Entry | Catalyst | Solvent | T/°C | Yield b /% |

| 1 | Pd/C | Toluene | 100 | 94 |

| 2 | — | Toluene | 100 | n.r. |

| 3 | PdCl2 | Toluene | 100 | n.r. |

| 4 | Pd(PPh3)4 | Toluene | 100 | n.r. |

| 5 | Pd(dba)2 | Toluene | 100 | 34 |

| 6 | Pd(PPh3)2Cl2 | Toluene | 100 | n.r. |

| 7 | PdCl2(dtbpf) | Toluene | 100 | n.r. |

| 8 | Pd/C | THF | 100 | 89 |

| 9 | Pd/C | EtOH | 100 | 47 |

| 10 | Pd/C | Dioxane | 100 | 86 |

| 11 | Pd/C | H2O | 100 | 80 |

| 12 | Pd/C | MeCN | 100 | n.p. |

| 13 | Pd/C | DMF | 100 | n.r. |

| 14 | Pd/C | Toluene | 120 | 86 |

| 15 | Pd/C | Toluene | 80 | 73 |

| 16 c | Pd/C | Toluene | 100 | 95(92) |

| 17 d | Pd/C | Toluene | 100 | 83 |

| 18 e | Pd/C | Toluene | 100 | 66 |

aReaction conditions: phenol (0.2 mmol), p-toluidine (0.2 mmol), catalyst (10 mol%), sodium formate (6 equiv.) and solvent (0.8 mL) under an argon atmosphere.

bYields were determined by GC analysis with mesitylene as internal standard; isolated yields in brackets.

cPd/C (7 mol%) was used.

dPd/C (5 mol%) was used.

eH2 (1 atm) was used instead of sodium formate.