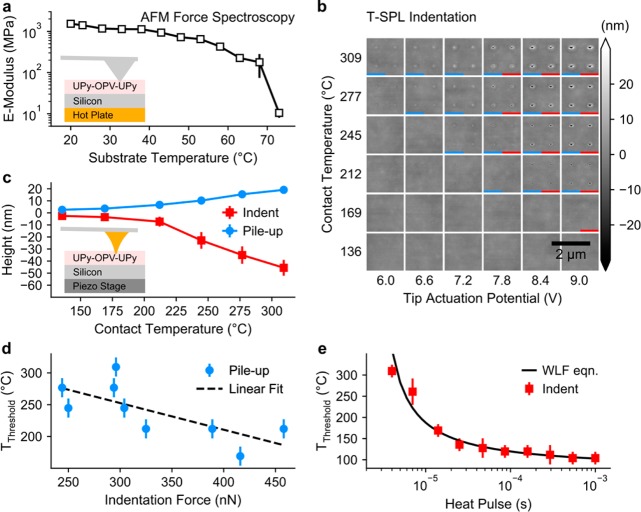

Figure 2.

Thermomechanical indentation of the TRL supramolecular polymer. (a) The elastic modulus of 20 ± 10 μm thick UPy–OPV–UPy films obtained from AFM-based force spectroscopy is plotted against the sample temperature. The inset depicts the experimental setup. (b) AFM topography images obtained from t-SPL indentation by varying the tip temperature between 130 and 310 °C and the indentation force between 200 and 500 nN (tip actuation potential 6.0–9.0 V). The colored bars indicate whether an indent was formed (red) or a pileup (blue). (c) The indentation depth and height of the pileup around the indent from thermomechanical indentation with a hot probe are plotted against the tip temperature. (d) The threshold temperature above which an indent or a pileup is formed is plotted against the indentation force and fitted with a linear function. (e) The temperature threshold to form an indent is plotted against the heating time and fitted using the Williams–Landel–Ferry equation for a constant tip actuation potential of 7.8 V.