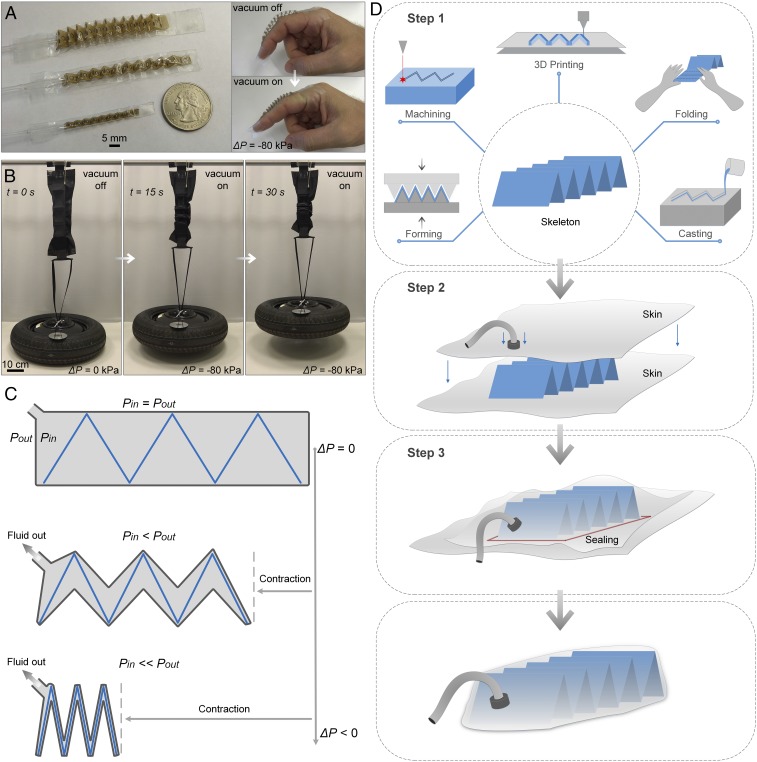

Fig. 1.

Design, fabrication, and resulting multiscale actuators. (A) Miniature linear actuators use polyether ether ketone (PEEK) zigzag origami structures as the skeletons and PVC films as the skins. These biocompatible materials make the actuators suitable for medical and wearable applications. (B) A large-scale high-power actuator is assembled using a zigzag skeleton composed of nylon plates (fold width = 10 cm). The skin is made of thermoplastic polyurethane (TPU)-coated nylon fabric. A car wheel (diameter ≈75 cm, weight ≈22 kg) is lifted to 20 cm within 30 s (Movie S3). (C) Principle of operation of the actuators. Contraction is mainly driven by the tension force of the skin. This force is produced by the pressure difference between the internal and external fluids. Removing fluid from the actuator will temporarily decrease the internal pressure. (D) Fabrication process. A standard actuator can be quickly fabricated in three simple steps: (step 1) skeleton construction using any of a number of techniques, (step 2) skin preparation, and (step 3) fluid-tight sealing.