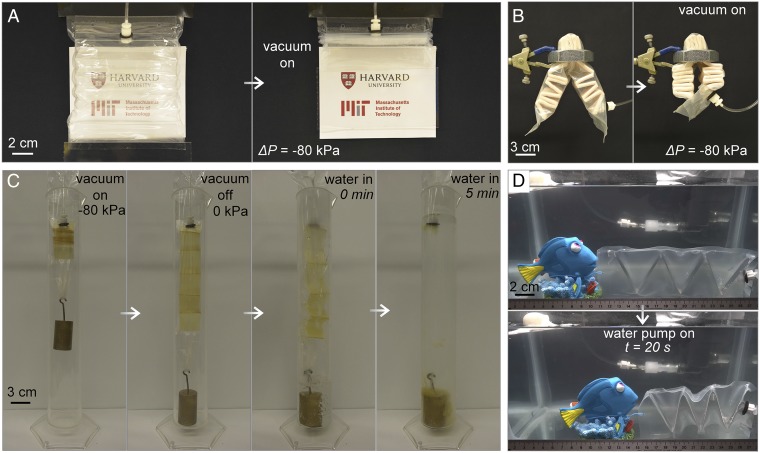

Fig. 2.

Linear zigzag actuators made of a variety of materials using different fabrication methods. (A) A transparent actuator lifts a clear acrylic plate. Skeleton material (): 0.254 mm transparent polyester sheet. Fabrication method (): laser cutting and manual folding. Skin material (): 0.102 mm transparent PVC film (Vinyl). Driving fluid (): air. (B) A soft linear actuator contracts well even when it is confined into a metal screw nut. : silicone rubber (M4601). : casting. : 0.24 mm TPU film. : air. (C) A vacuum-driven water-soluble actuator is dissolved in hot water (≈ 70 °C) within 5 min. : polyvinyl alcohol (PVA). : 3D printing. : 0.025 mm PVA film. : air. (D) A water pump-driven hydraulic actuator pulls an underwater object for 3.5 cm in 20 s. : 0.254 mm stainless steel (316). : manual forming. : 0.24 mm TPU film. : water.