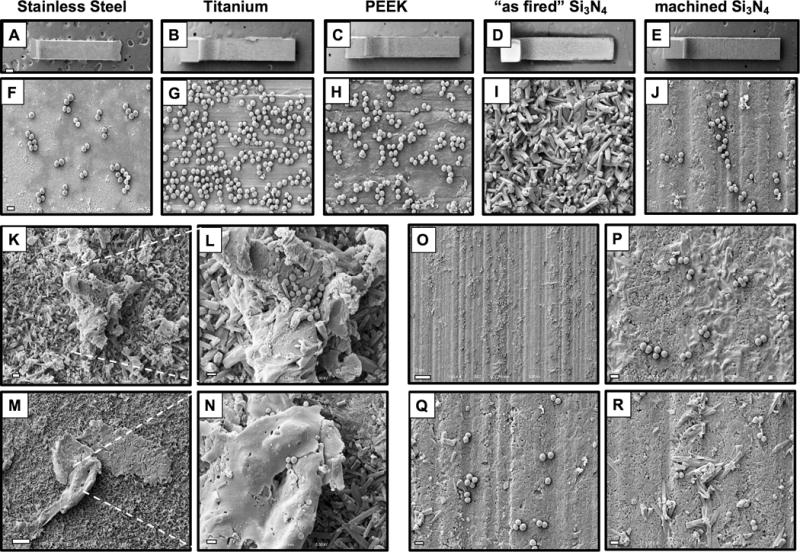

Figure 2. Native “as fired” Si3N4 implant surfaces are highly resistant to MRSA adherence in vitro.

SS, Ti, PEEK, “as fired” Si3N4 and machined Si3N4 implants (n=4) were submerged in an overnight culture (O.D. = 0.7 at 630nm) of USA300LAC, air dried, and processed for SEM. Representative low power images of the L-shaped implants are shown at ×30 (A-E; scale bar in A = 200μm), and higher power images of regions containing adherent MSRA are shown at ×5,000 (F-J; scale bar in F = 1μm). Of note is that we failed to identify bacteria that were directly adhering to native “as fired” Si3N4 implant surfaces (I). However, bacteria were only observed on foreign material and culture debris (TSB precipitate and lysed bacteria) that adhered to the “as fired” Si3N4 implant surfaces (K ×2,000; scale bar = 5μm; inset image (L) ×5,000 scale bar = 1μm) and (M ×1,000 ; scale bar = 10μm; inset image (N) ×5,000 scale bar = 1μm). In contrast, bacteria were readily found on machined Si3N4 implant surfaces (O ×1,000 scale bar = 10μm). High power images of non-uniformly machined areas demonstrated preferential bacterial adhesion to the flatter surfaces, and lack of bacterial adhesion to incompletely machined surface structures (P-R ×5,000 scale bar = 1μm).