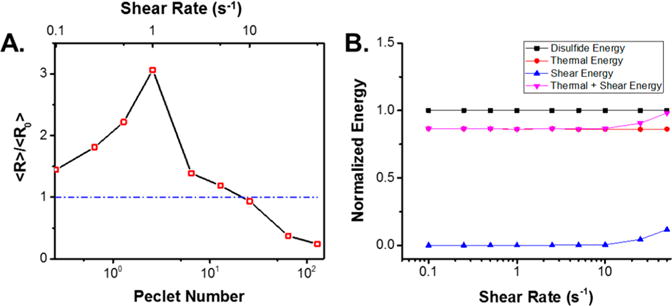

Figure 5.

(A) Plot of the mass average normalized radius versus applied shear rate (top axis) and Peclet number (bottom axis). Plotting the aggregation behavior versus the shear rate and Peclet number allows for the determination of ideal processing parameters to prevent excessive aggregation and particle breakup of Qβ in PLGA and other polymeric systems during melt-processing (B) Applied energy to the particles versus total particle disulfide energy analysis indicating the thermal and shear energy approached the level of disulfide energy in the Qβ particles at 25 and 50 s−1 shear rates, resulting in the observed particle breakup.