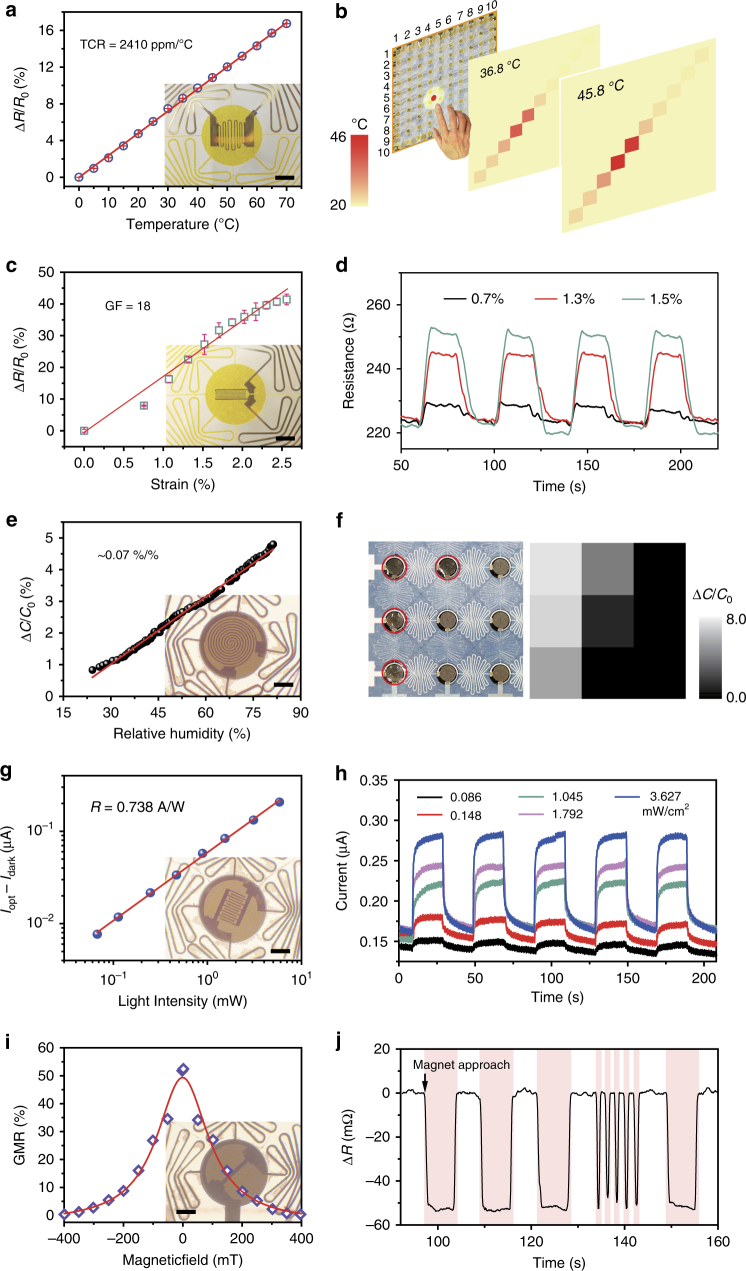

Fig. 3.

Multifunctional sensing performances. a, b Temperature sensing. a The relative resistance of the temperature sensor changes linearly with temperature; the inset depicts a Pt thin film temperature sensor fabricated on an SCMN. b Spatial temperature distribution recognition for temperatures close to 36.8 °C and 45.8 °C after placing a heat source above an SCMN. c, d In-plane strain sensing. c The relative resistance change increases with increasing applied strain; the inset shows a Constantan alloy thin film in-plane strain sensor mounted on an SCMN. (Error bars represent the fluctuation between normalized resistance and applied strain at each point.) d The temporal resistance changes for different curvatures of the strain sensor under cyclical bending (Strain: 0.7%, 1.3% and 1.5%). e, f Humidity sensing. e The change in capacitance is linear with increasing relative humidity (RH); the inset is an image of a humidity sensor on an SCMN. f Image of water droplets covering a partial area of a humidity senor array (left) and a corresponding map of the regional capacitance change (right). The red circles indicate where the droplets are placed. g, h Light sensing. g The photocurrent generated by UV light (355 nm) increases linearly with the light intensity; inset is an image of an optical sensor. h Repeatable UV response under different illumination intensities at a 5 V bias. i, j Magnetic sensing. i The GMR characteristics of a Co/Cu magnetic sensor; inset is an image of a magnetic sensor on an SCMN. j The recorded resistance changes when a magnet cyclically approaches (pink) and withdraws (white) from the sensor. Inset scale bars: 500 μm