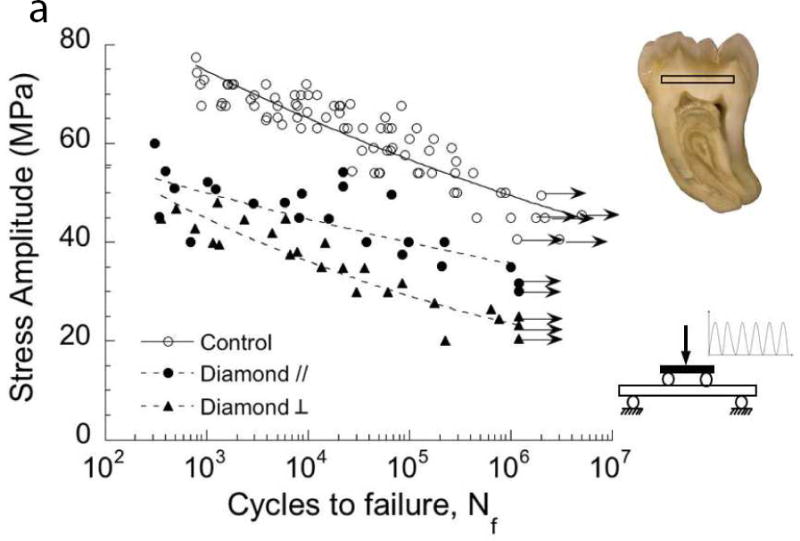

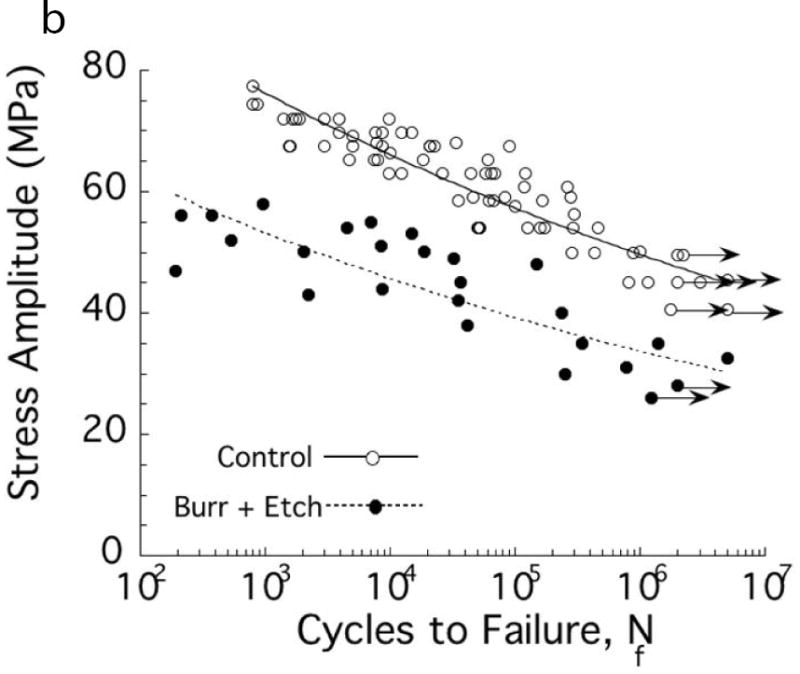

Fig. 1.

Importance of damage introduced during cavity preparations on the fatigue strength of coronal dentin. The “control” in these two diagrams consists of beams of coronal dentin prepared with diamond slicing wheels, and with average surface roughness (Ra) of less than 0.2 μm. (A) Comparison of the fatigue strength after cutting treatments with medium diamond abrasive and water spray irrigation. Results are shown for cutting parallel (//) and perpendicular (□) to the length of the beam, which is important to the orientation of damage. Data points with arrows represent beams that did not fail and the test was discontinued. (B) Comparison of the fatigue strength distribution of the control with dentin beams subjected to a bur cutting treatment followed by a 15 second etch with 37.5% gel. Cutting was performed with a 6-flute tungsten carbide straight fissure bur and commercial air turbine with water spray irrigation.

A: Adapted from Majd B, Majd H, Porter JA, et al. Degradation in the fatigue strength of dentin by diamond bur preparations: Importance of cutting direction. J Biomed Mater Res B Appl Biomater 2016;104(1):39–49; with permission.

B: Adapted from Lee HH, Majd H, Orrego S, et al. Degradation in the fatigue strength of dentin by cutting, etching and adhesive bonding. Dent Mater 2014;30(9):1061–72; with permission.