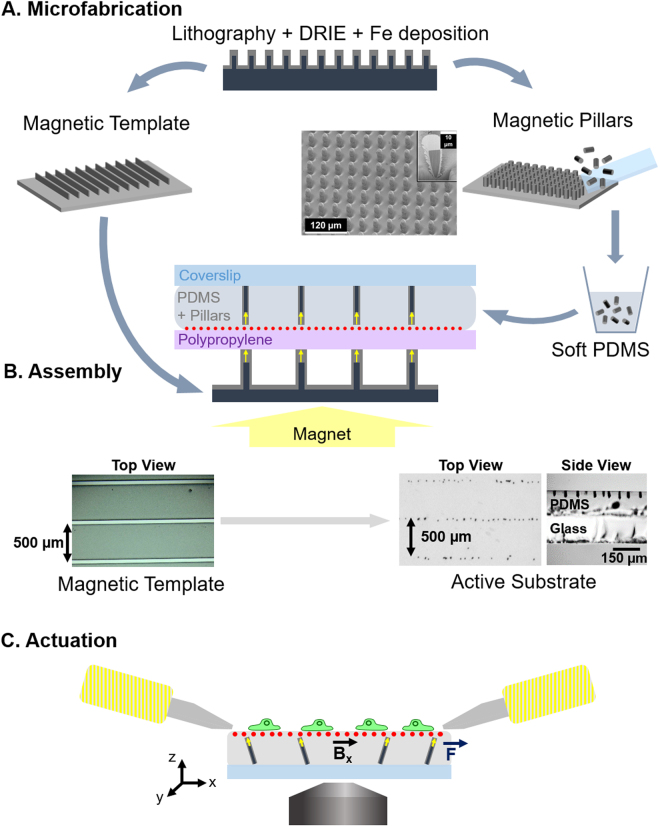

Figure 1.

Experimental workflow. (A) Magnetic micro-pillars and template are made by optical lithography followed by deep reactive ion etching (DRIE) and iron deposition by sputtering. The magnetic pillars are mechanically detached from the wafer and mixed with soft PDMS prior to casting between a sheet of polypropylene coated with fluorescent beads and a coverslip. (B) The resulting sandwich structure is positioned on a magnetic template laid on a large permanent magnet, so as to align the pillars vertically (side view) and organize them according to the pattern of the template (top view). (C) After peeling off the polypropylene sheet, coating the surface with proteins and plating cells on the top, the substrates are placed in the magnetic field generated by two electromagnets so as to actuate the pillars via a magnetic torque. The actuation setup is mounted on a microscope to quantify the local deformation of the surface by tracking the fluorescent beads and to follow the response of the cells to the mechanical stimulation.