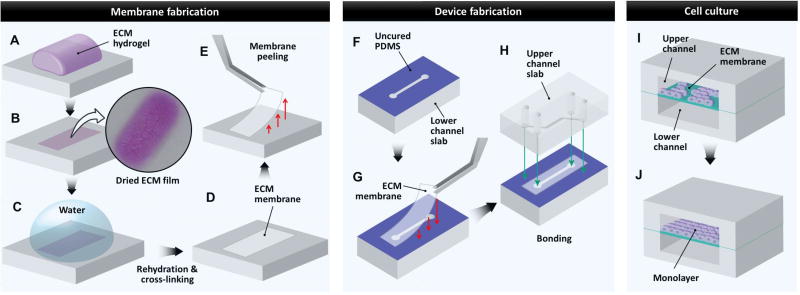

Figure 1. Fabrication of ECM-derived membrane inserts for microfluidic cell culture.

A. ECM hydrogel cast on PDMS surface. B. Dehydration of ECM hydrogel to yield a dried ECM film. C. Rehydration of dried ECM film to remove salts and other impurities followed by transglutaminase cross-linking (for fabrication of COL+MAT). D. Dehydration of purified and cross-linked ECM film to yield ECM membranes used as microfluidic cell culture inserts. E. Peeling of ECM membrane from underlying PDMS surface using forceps, followed by manual trimming with scissors if necessary. F. Microfluidic channel slabs fabricated by soft lithography are stamped with uncured PDMS to facilitate bonding of ECM membrane inserts over microfluidic channels. G. An ECM membrane is placed over the lower channel using forceps. H. The upper channel slab stamped with uncured PDMS is bonded to the lower channel slab to create an enclosed three-layer channel system. The cross-sectional view of the fully assembled device is shown in I and J. I. Cells are seeded on the ECM-derived membrane inserts in microfluidic devices. J. During perfusion culture, the seeded cells proliferate on the membrane surface to form stable, confluent monolayers in microdevices.