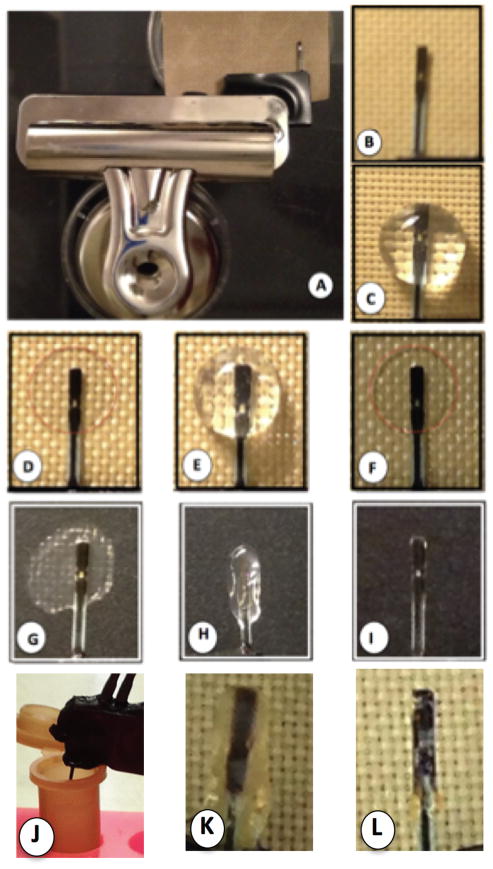

Figure 1. Coating of Glucose Sensors in vitro Utilizing Cultrex Basement Membrane Extract (Cultrex) and Crosslinked Cultrex Preparations.

To produce a simple and reproducible coating of glucose sensors with Cultrex for in vitro and in vivo studies, a clamp based system, which utilizes a standard magnetic office clamp (OC), a modified Abbott glucose sensor (GS) and a polytetrafluoroethylene sheet (PTFE) was utilized (A). The Abbott sensor is centered on top of the PTFE sheet (B), and 50ul of dialyzed Cultrex is added on top of the sensor (C) and allowed to dry at 37°C, resulting in a thin protein layer on the sensor and associated PTFE sheet (D, red dotted line). The sensor is then removed from the PTFE sheet, flipped over and an additional 50ul of dialyzed Cultrex is added (E) and allowed to dry (F). This process can be repeated as needed to form a Cultrex coating on the sensor. Finally the sensor with a dry Cultrex coating is removed from the PTFE sheet (g), dipped in sterile water (h) and then allowed to dry at 37°C until dry (i). Cross-linked Cultrex (X-Cultrex) sensors were produced in the same process as the non-cross-linked Cultrex sensors, except with the addition of two steps in which the coated dry Cultrex coated sensors are dipped in 0.2 – 0.4% glutaraldehyde for 5 minutes, and then dipped in sterile pyrogen free water for at least 1 hour. Then the X-Cultrex coated sensors are dried as described above at 37°C. The resulting non-cross-linked (Cultrex) or cross-linked Cultrex (X-Cultrex) sensor is then utilized for in vitro studies, or implanted subcutaneously for in vivo studies.