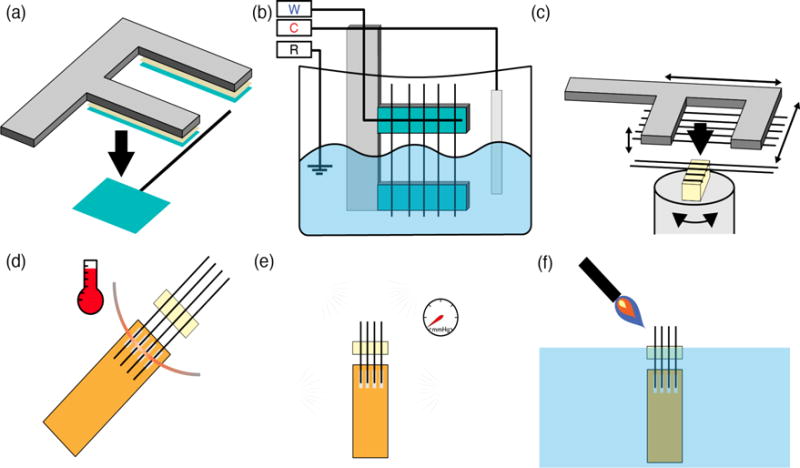

Figure 1.

Schematic of the carbon fiber array assembly process. (a) First, fibers are placed on a harp-like structure to improve positioning and handling during subsequent steps. (b) Next, carbon fibers are partially submerged into an indium plating bath and cyclic voltage sweeps are applied to induce electrodeposition of indium onto one end of the fibers. W: carbon fiber working electrodes; C: indium counter electrode; R: Ag|AgCl reference electrode. (c) Using the fiber harp, the indium plated carbon fibers can be precisely positioned in a microgroove alignment clip. The alignment clip securely retains already positioned fibers, preventing accidental jostling and displacement during subsequent fiber insertions. (d) A polyimide lead with indium plated pads is brought in contact with the aligned, indium plated carbon fibers, and the two are microsoldered with a fine heating element. (e) A 1 μm thick insulating layer of Parylene-C was vacuum deposited over the entire surface of the assembled array. (f) The carbon fibers are trimmed to length and the electrode tips of the electrodes are fire-sharpened at the air-water interface.