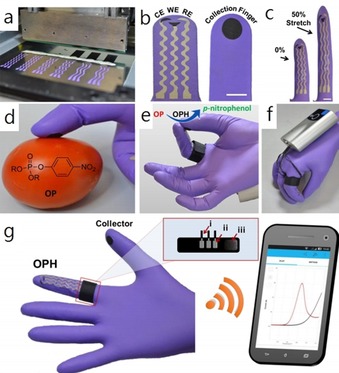

Figure 14.

Flexible glove biosensor: fabrication, design, and performance. a) Image of the serpentine stencil design employed for printing the glove‐based stretchable device. b) Schematic of (left) the biosensing scan finger (index finger) containing a smiling face shape carbon‐based counter (CE), working electrode (WE), and Ag/AgCl‐based reference electrode (RE), and (right) collecting thumb with its printed carbon pad; scale bar: 10 mm. c) Photographs of the biosensing index finger under 0 % (left) and 50 % (right) linear stretch; scale bar: 10 mm. d) On‐glove swiping protocol for sampling chemical threat residues from tomato and stainless‐steel surfaces. e) On‐glove sensing procedure by joining the index finger (scan) and thumb (collector) to complete the electrochemical cell. f, g) Photographs of the wearable glove biosensor consisting of a sensing finger containing the immobilized organophosphorus hydrolase (OPH) enzyme layer and the collector/sampling finger. The electrodes are connected by an adjustable ring bandage to the portable potentiostat (attached to the back of the hand) for on‐site detection with wireless communication to a smart phone for rapid presentation of the voltammetric results. The inset shows a schematic of the interface between potentiostat and glove sensor. The connections consist of a Velcro fabric (iii) containing the aluminum‐tape based pins (ii) that are adjusted as a ring with the glove sensing connectors and the wiring (i) with the potentiostat. Reproduced from Ref. 56 with permission of the American Chemical Society.