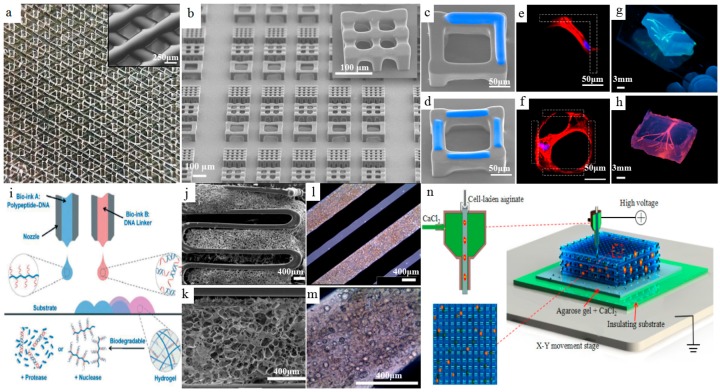

Figure 6.

Bioprinted hydrogels. (a) Macroscopic view of additive-manufactured five-layer gelatin. Inset: Magnification of scaffold porosity, reprinted from [61] with the permission of Nature Publishing Group, Copyright 2017; (b) SEM images of 3D cubic microscaffolds via vat photopolymerization process. (c,d) SEM images of the cubic microscaffolds with in situ printed GelMA (blue); (e,f) the fluorescent staining of f-actin (red) and nuclei (blue) of the human mesenchymal stem cells (hMSCs) cultured in the corresponding microscaffolds (gelation shown as the dashed area), reprinted from [62] with the permission of Nature Publishing Group, Copyright 2017; (g) Photographs of the bioprinted agarose templates (green); (h) Respective microchannels perfused with a fluorescent microbead suspension (pink, diameter of microchannels: 500 μm), reprinted from [63] with the permission of Royal Society of Chemistry, Copyright 2014. (i) Scheme of 3D bioprinting of the polypeptide–DNA hydrogel, reprinted from [66] with the permission of John Wiley and Sons, Copyright 2017; (j,k) SEM images of hybrid structure of cartilage decellularized extracellular matrix (cdECM) with PCL framework; (l,m) microscopic images of cell-printed structure of adipose decellularized extracellular matrix (adECM) with PCL framework, reprinted from [69] with the permission of Nature Publishing Group, Copyright 2014; (n) Schematic of coaxial nozzle-assisted electrohydrodynamic cell printing, reprinted from [73] with the permission of WHIOCE publishing, Copyright 2017.