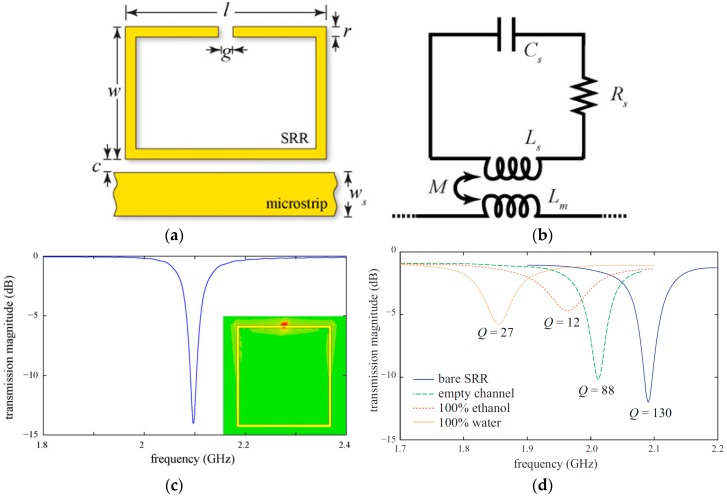

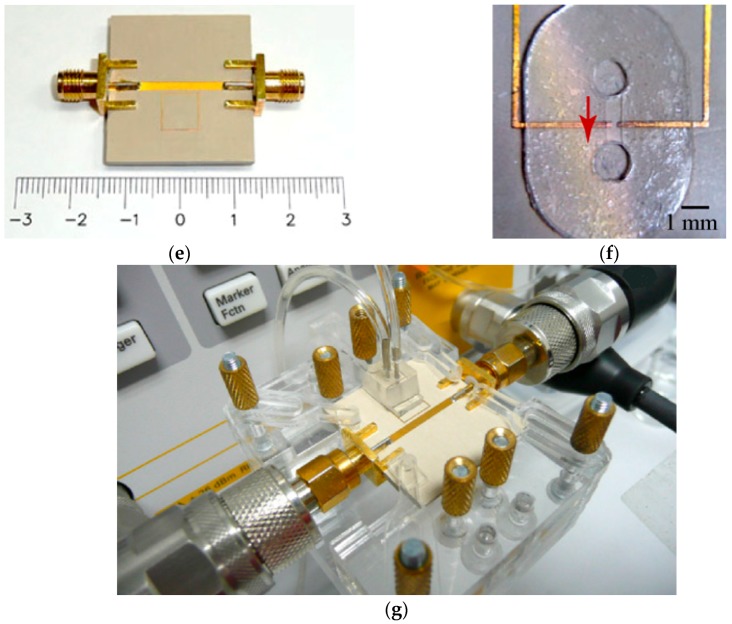

Figure 2.

(a) Microstrip-coupled SRR etched on the top of a substrate; (b) Equivalent circuit of the proposed resonator with Lm represents the inductance of microstrip line, {RLC}s for the parasitic elements of the ring resonator, and M for the mutual inductance between SRR and microstrip line; (c) Simulated transmission magnitude of the proposed resonator, and in inset electric field magnitude at 2.1 GHz (resonant frequency) with the highest electric field at the split-gap of ring resonator; (d) Measured transmission magnitude showing various profiles of the proposed chemical sensor, 100% ethanol being the lossy chemical showing the lowest Q factor as compared to air and water; (e) Fabricated prototype assembled with two SMA (SubMiniature version A) connectors; (f) A zoom-in view showing the microfluidic channel accurately positioned on the SRR gap. The red arrow indicates the direction of fluidic flow; (g) Fully assembled sensor with polymer tubes delivering liquid into the chamber and coaxial cables connected to the vector network analyzer (Redrawn from [33]).