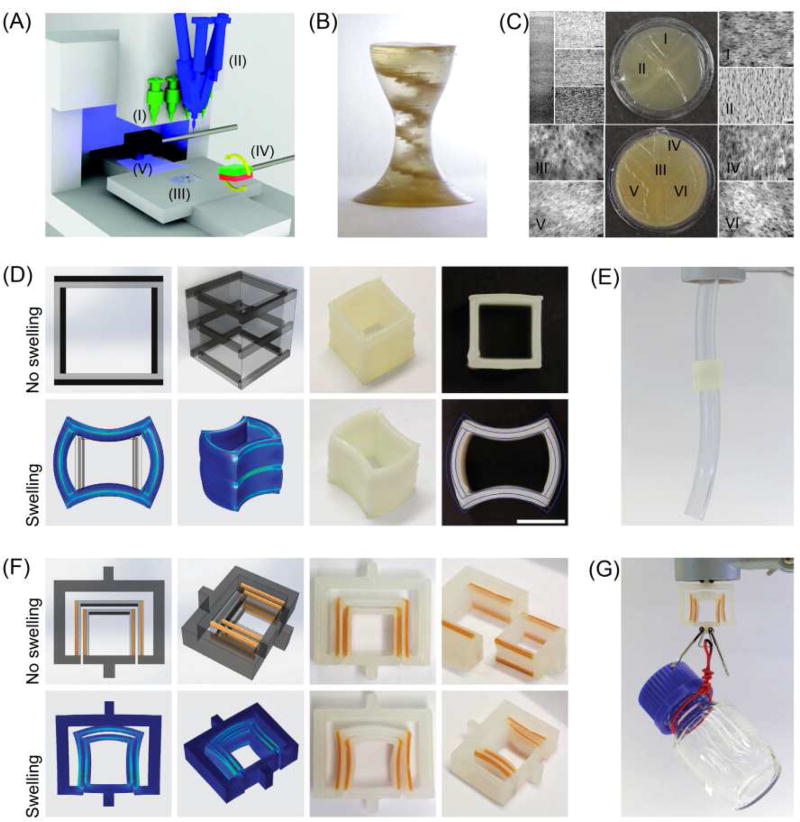

Figure 4.

(A) Direct ink-writing hardware equipped with multiple dispensers. (B) Actual MM-3D printed object with internal helicoidal staircase. Scale bar, 5mm. (C) (C; Top) Photograph of the top layer of the structure. (C; Bottom) Photograph of the bottom layer of the structure. (D) (D; Top) Drawings and actual printed cuboids before the shape change. (D; Bottom) Finite element simulations and actual pictures of the cuboids after the shape change. Scale bars, 10 mm. (E) Cuboid-mediated fastening of two tubes achieved through the shape change of the printed object. Scale bar, 20 mm. (F) (F; Top) Drawings and actual printed key–lock objects before the shape change. (F; Bottom) Finite element simulations and actual pictures of the key–lock structure after the shape change. Scale bars, 15 mm. (G) Mechanical fastening enabled by the shape changing key–lock architecture. Scale bar, 15 mm. In all drawings, light and dark grey colors indicate soft and hard phases, respectively. Adapted with permission from [36].