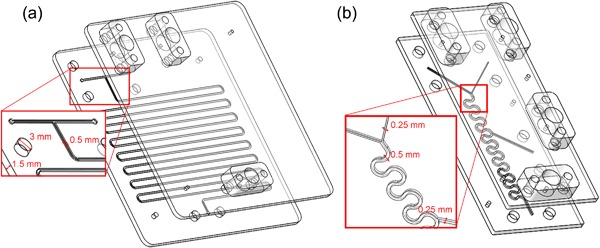

Figure 2.

(a) Exploded view of the transketolase microreactor made out two layers of poly(methylmethacrylate) (PMMA), a reaction layer and a cover layer; detail view shows the geometry of the inlet channels and the T‐junction with the reaction channel; six large bores in each layer hold the connector bars for the fluidic interconnection. (b) Exploded view of the micromixing device made out two layers of PMMA, a layer with the mixing structure and a cover layer. Detail view shows the geometry of the inlets; the Y‐junction at the top of the meandering channel to add the co‐substrate for the transaminase‐catalyzed reaction, and the inlet in the middle of the channel to introduce the transaminase