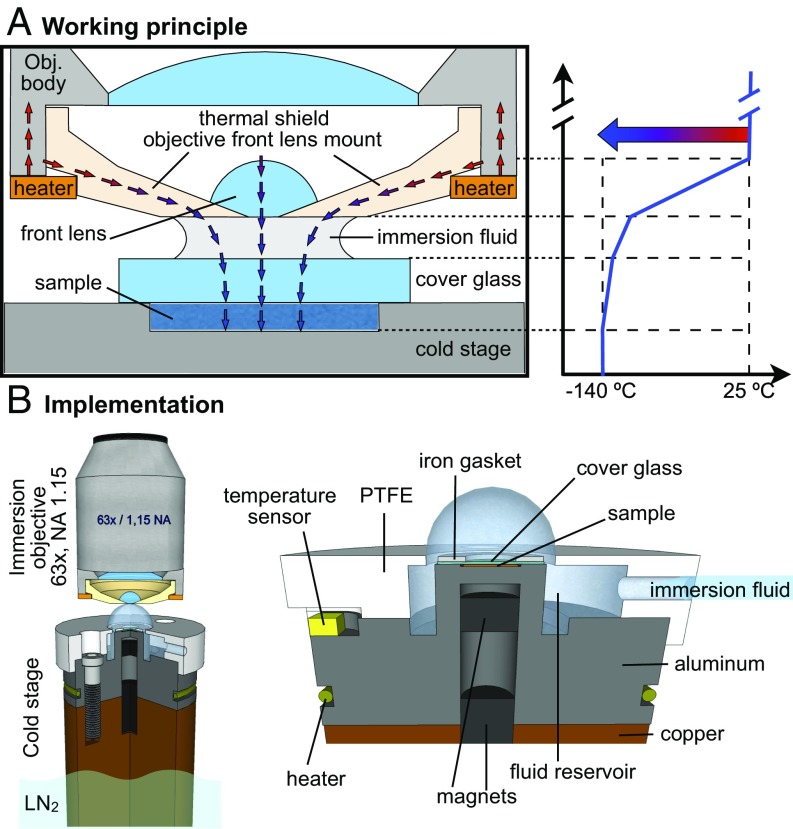

Fig. 1.

(A) Schematic cross-section of an immersion objective with the front lens mount made of Macor operating as a thermal shield. The heat flows across the sample, cover glass, immersion fluid, front lens, and ceramic mount. The low thermal expansion coefficient of the machinable ceramic allows for reducing the thermal stresses. The high thermal resistance of Macor allows confining most of the temperature gradient in the front lens mount, as shown in the diagram. Note that due to the high thermal conductivity of the metallic cold stage and the intimate contact with the sample, the stage temperature closely reflects the temperature of the sample. (B) The cold stage used for the implementation of cryoimmersion microscopy was designed to keep both sample and cryoimmersion fluid at a stable temperature by combining heating and temperature sensing. The stage is composed of two parts, a bottom copper bar, which is in direct contact with liquid nitrogen, and a top anodized aluminum post. The sample is placed on top of the aluminum post and is in direct contact with the metal below a coverslip. The coverslip and sample are secured magnetically to the post by using an iron gasket and a magnet glued inside the aluminum post. The immersion fluid is supplied to the reservoir through a channel in the polytetrafluoroethylene (PTFE) cap. The opening in the PTFE cap allows forming a cold drop around the sample.