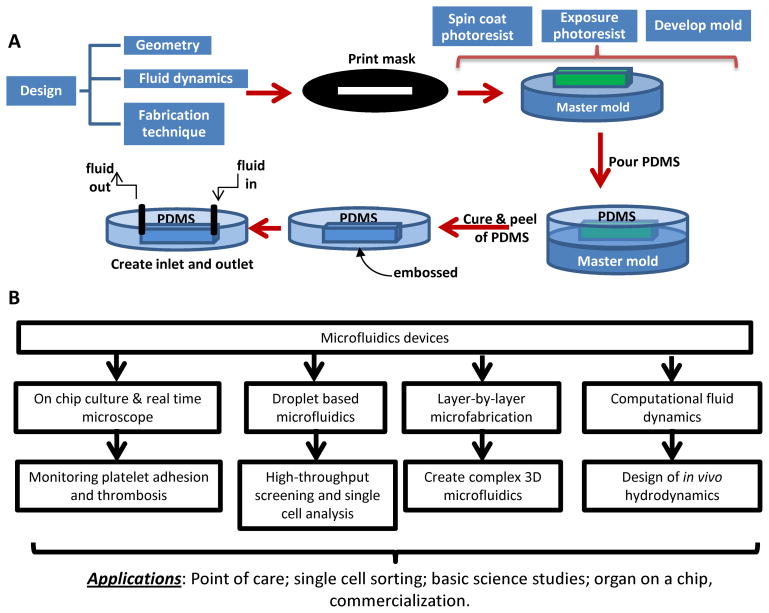

Figure 1. Fabrication of microfluidics flow cells using polydimethylsiloxane replica molding.

A. Fabrication starts with the design of the geometry and fluid dynamics that are of interest. The photolithography steps make use of the negative photoresist, e.g. SU-8. Exposure of this resist to UV radiation in the presence of the pattern mask results in the master mold. Then polydimethylsiloxane (PDMS) is used to cast microfluidic devices containing pre-designed structures reflected by the mold. In the final step, the PDMS mold is peeled from the master template and assembled into a flow device. B. Design and applications of microfluidics. Online figure is available in color.