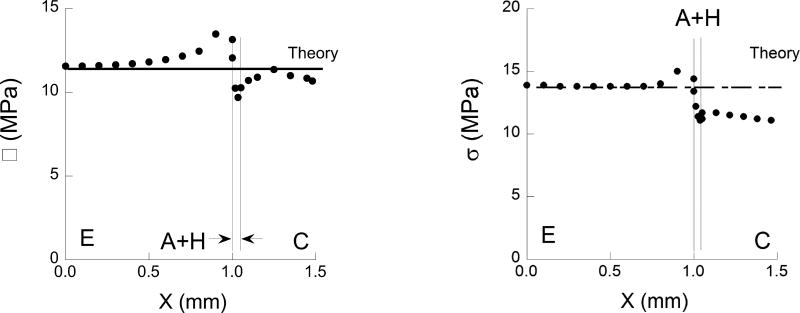

Figure 4.

The normal stress distribution in the x-direction along the tensile surface (i.e. the region of maximum normal stress) of the twin interface specimen for a flexural load of 10 N. The normal stress is acting in the x-direction, normal to the bonded interface. The stress is plotted from the center of the enamel or DEJ section (x=0) to the right, across the adhesive layer and within the resin composite. The stress distribution obtained from the finite element analysis (dotted line) is presented along with that estimated using beam theory (solid line). a) enamel bonding without the DEJ, b) bond including enamel and dentin as shown in Fig 3(a). Note the difference in the axis range for these two plots. In both cases, there is a concentration of stress in the hard tissue adjacent that develops adjacent to the bonded adhesive. The largest stress develops in the bonded interface involving the DEJ.