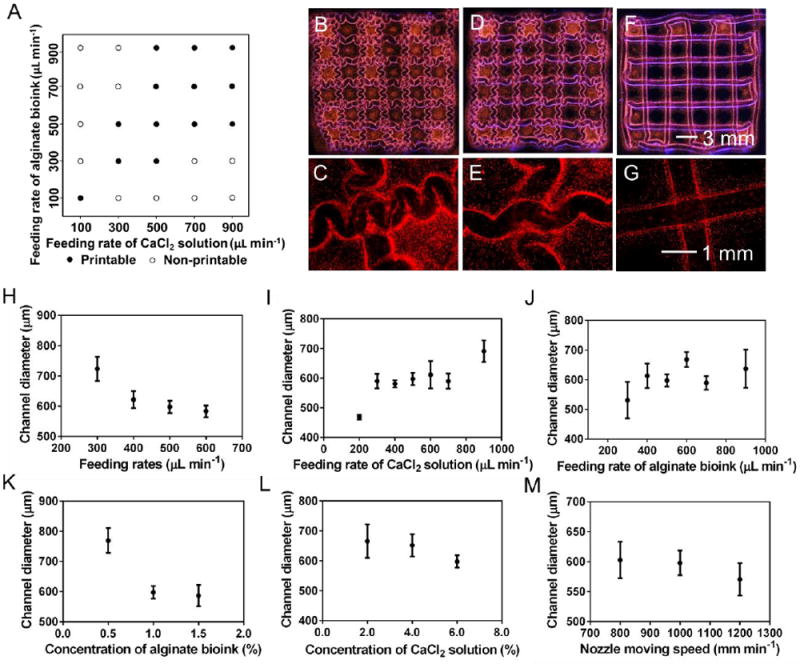

Figure 2.

Bioprinting performance of alginate bioinks. A) Printability map showing the effect of feeding rates of the CaCl2 solution and the alginate bioink. B-G) Photographs showing bioprinted hollow constructs with curved and straight channels, the feeding rates of the CaCl2 solution and the alginate bioink (equal rates) were (B, C) 900 μL min-1, (D, E) 700 μL min-1, and (F, G) 400 μL min-1. H-M) Channel diameter of the hollow constructs as a function of (H) feeding rates of the CaCl2 solution and the alginate bioink (equal rates), (I) feeding rate of the CaCl2 solution, (J) feeding rate of the alginate, (K) concentration of the alginate bioink, (L) concentration of the CaCl2 solution, and (M) nozzle moving speed. Unless otherwise noted, the concentration of the CaCl2 solution and the alginate bioink, the feeding rates of the CaCl2 solution and the alginate bioink (equal rates), and the nozzle moving speed were kept constant at 6.0% and 1.0%, 500 μL min-1 and 500 mm min-1, respectively. The core-sheath nozzle was made using 23G/28G needles.