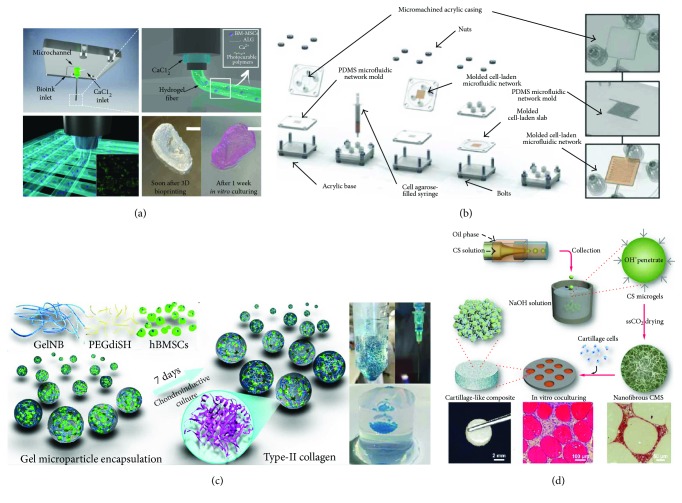

Figure 3.

Application of microfluidic and bioprinting technologies for the development of 3D cartilaginous constructs. (a) Schematic representation of the custom-made dispensing coaxial system: calcium chloride flows in the external nozzle while the bioink is supplied through the inner one. Hydrogel fibers form immediately at the tip of the inner nozzle when the two solutions come into contact. Real-size neonatal ear can be obtained with a high printing resolution (≈100 μm). Scale bar = 10 mm (3D bioprinting method reported in [71]). (b) Fabrication process of a cell-laden agarose construct with an incorporated microfluidic serpentine to enhance oxygen and nutrient transport (adapted from [66]). (c) Schematic diagram of chitosan microsphere production through a coaxial glass microcapillary device. Each nanofibrous microsphere is seeded with articular chondrocytes, and the deposition of newly generated ECM tightly bridges the microspheres into a clinically relevant 3D construct (adapted from [21]). (d) Schematic representation of hydrogel microspheres with encapsulated BMSCs produced by a simple syringe-based system. The obtained microspheres can be injected into the lesion site, as demonstrated by the injection into an agarose gel model, which mimics an articular cartilage defect (adapted from [20]).