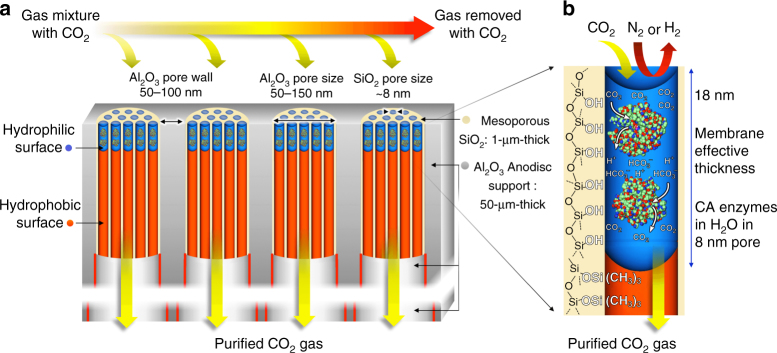

Fig. 2.

Enzymatic liquid membrane design and mechanism of CO2 capture and separation. a The membrane is fabricated by formation of ~1-µm-deep oriented arrays of 8 nm diameter cylindrical silica [SiO2] mesopores within the larger 50–150-nm pore channels of a 50-μm-thick porous alumina [Al2O3] Whatman© Anodisc support. b Using atomic layer deposition and oxygen plasma processing (described in text and Fig. 4) the silica mesopores are engineered to be hydrophobic (trimethylsilyl (Si(CH3)3) surface groups) except for an 18-nm-deep region at the pore surface, which is hydrophilic (≡Si-OH surface groups). Via capillary condensation, CA enzymes and water spontaneously fill the hydrophilic mesopores to form an array of nano-stabilized CA enzymes with an effective CA concentration >10× of that achievable in solution. CA catalyzes the capture and dissolution of CO2 as carbonic acid (HCO3–) moieties at the upstream surface and regeneration of CO2 at the downstream surface (see Fig. 1c). The high concentration of CA and short diffusion path length maximizes capture efficiency and flux